Search standard for testing available at SKZ

Search standard for testing available at SKZ

Optical tests

Optical testing is an indispensable tool in modern materials science and quality control, especially when it comes to plastics and plastic components. The measurement methods use electromagnetic waves, which generally have wavelengths in the visible light range, to analyze the properties of a material or component without physical contact. This makes optical testing a fast, efficient and, above all, non-destructive testing technique. Optical testing can be used to identify deviations in color, gloss and transparency as well as surface defects such as scratches, flaking, bubbles, inclusions and, in some cases, internal inhomogeneities with high precision.

Optical testing therefore has a very wide range of applications and can be used in almost all sectors of industry. For example, in many cases the color conformity of plastic parts is a decisive quality feature and ultimately ensures the satisfaction of the end consumer. In addition, gloss measurements also play an important role in assessing the aesthetic quality of high-quality surfaces, whereas the degree of transmission or haze is often critical for the consistent functionality of transparent plastic parts.

Further details on this process

- Color

according to DIN 53236, DIN EN ISO 11664-4, ISO 7724-2 and ISO 7724-3 - Gloss

according to DIN EN ISO 2813 - Gray scale

according to DIN EN 20105-A02 and DIN EN 20105-A03 - Opacity

according to DIN EN ISO 7686 and TCS 2114.2 - Transmission (light transmission) and haze (opacity)

according to to ASTM D 1003

Spectrophotometer

This device determines the color of plastic samples under standardized light conditions in order to determine exact colour coordinates in accordance with international standards such as DIN EN ISO 11664-4 (CIE Lab*).

Gloss meter

Gloss meters determine the gloss level of a surface by measuring the reflectance at a defined angle. They are essential for assessing surface quality.

Haze meter and transmission meter

These instruments are crucial for determining the light transmission (transmittance) and haze of transparent or translucent plastics. Some modern spectrophotometers can also be used for such measurements with a special setting mode.

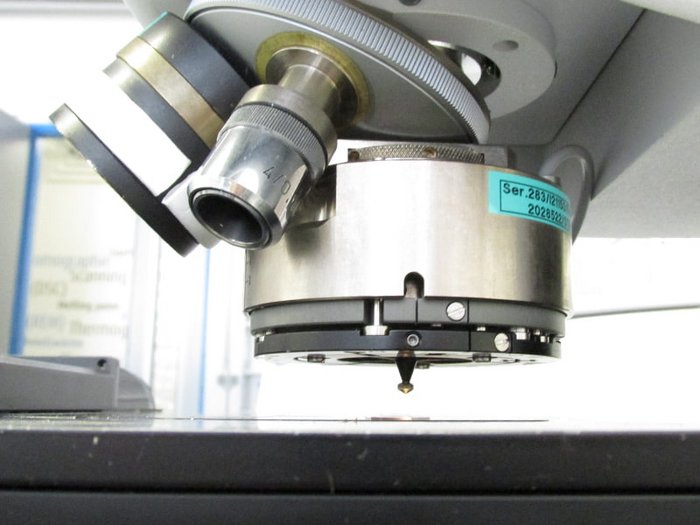

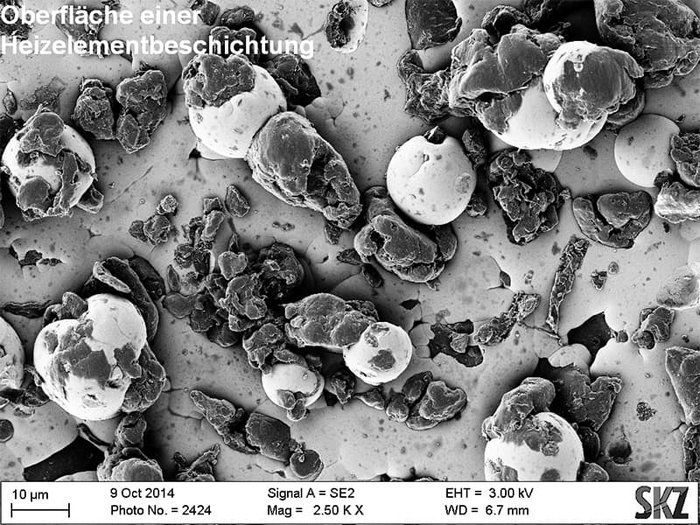

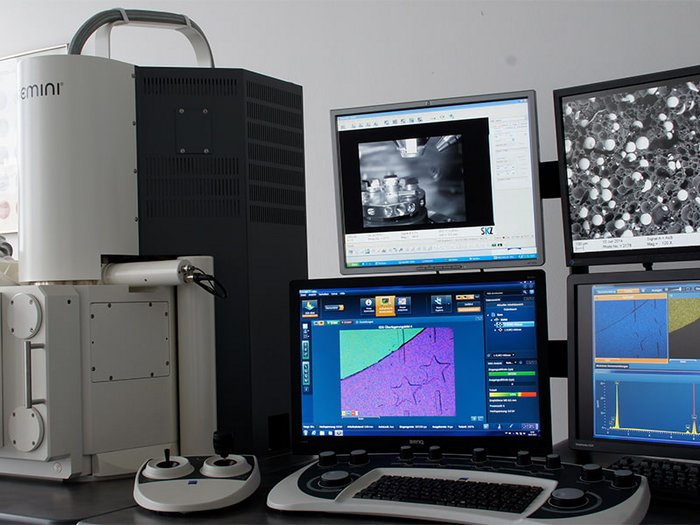

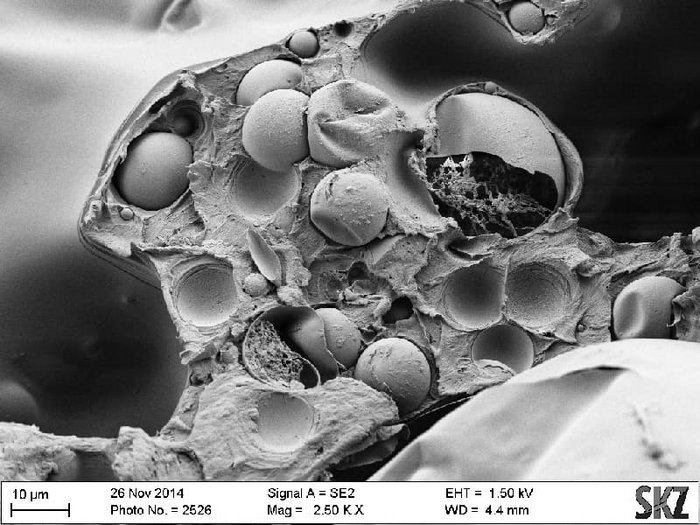

Microscopes with image processing

Microscopes, combined with advanced image processing software, are essential for analyzing surface defects, the microstructure of plastic mixtures or the detection of inclusions. They enable detailed observation of samples at high magnification and provide valuable information about material defects or the homogeneity of a mixture. Further information on microscopy

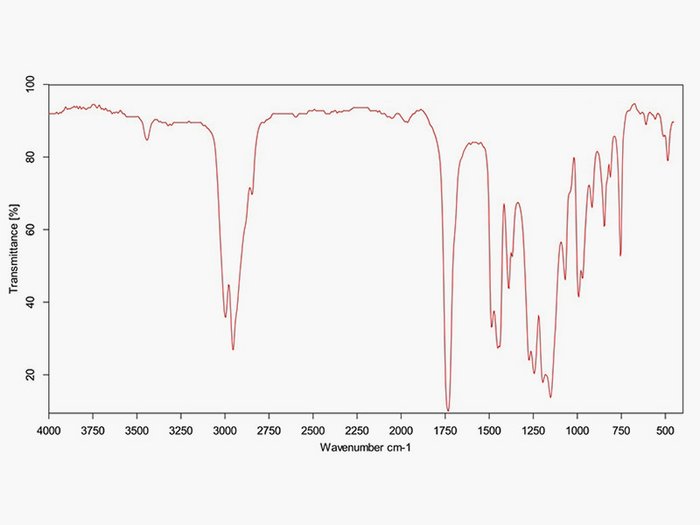

UV-VIS spectrometer

Some optical tests require samples to be analyzed under UV or infrared light. UV-VIS spectrometers offer the flexibility to measure absorption and transmission properties over a wide wavelength range, which can be important for the evaluation of UV stabilizers or other additives in plastics. Further information on spectroscopy

For color and gloss measurements, the sample sizes are usually defined in established test or product standards, which ensures that these measurements are reproducible and comparable.

For color measurements, it should generally be noted that the samples should be large enough to completely cover the measuring window of the spectrophotometer, which usually means a minimum size of about 25 mm x 25 mm. This size also ensures a representative measurement for most samples.

For gloss measurements, samples with an area of at least 50 mm x 50 mm are typically used in order to be able to carry out standard-compliant measurements. For high-gloss or matt surfaces, specific measurement conditions or larger samples may be necessary to correctly record the reflective properties.

Samples with an area of at least 50 mm x 50 mm are also recommended for other visual assessments (e.g. determining the gray scale).

It should be noted that for all standardized optical tests, samples with a sample surface that is as flat, clean and homogeneous as possible should be selected. Irregularities, inclusions or impurities can significantly influence or falsify the measurement results.

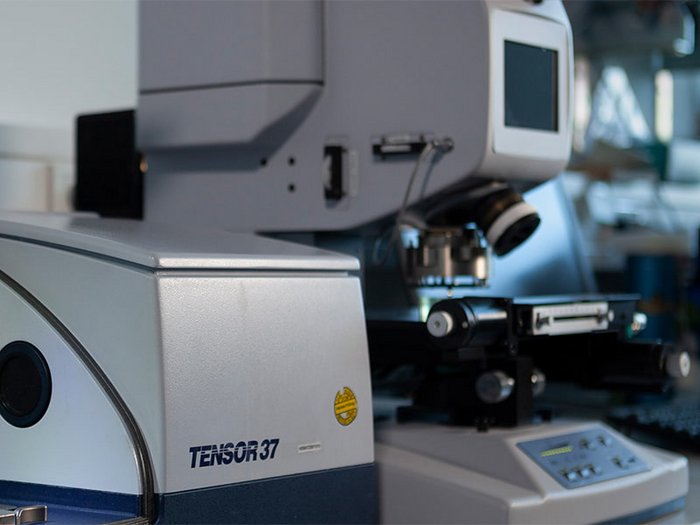

State-of-the-art equipment for the best results and products

In our various laboratories and test rooms, we have a wide range of testing equipment for different methods of plastics testing.

97076 Würzburg

Telefon: +49 931 4104-0

E-Mail: info@skz.de

Route berechnen

97082 Würzburg

Telefon: +49 931 4104-123

E-Mail: training@skz.de

Route berechnen

Köthener Str. 33a

06118 Halle (Saale)

Telefon: +49 345 53045-0

E-Mail: halle@skz.de

Route berechnen

Rauher Grund 9

72160 Horb am Neckar

Telefon: +49 7451 62457-0

E-Mail: horb@skz.de

Route berechnen

Woltorfer Str. 77, Halle G

31224 Peine

Telefon: +49 5171 48935

E-Mail: peine@skz.de

Route berechnen

Weißenbacher Str. 86

95100 Selb

Telefon: +49 9287 99880-0

E-Mail: ezd@skz.de

Route berechnen

Via Buonarotti 175

20900 Monza, Italy

Telefon: +39 039 281561

E-Mail: info@prochema.it

Route berechnen

Str. Iancu Jianu, nr. 26

500178 Braşov, Romania

Telefon: +40 268 412 559

E-Mail: office@plastics-bavaria.ro

Route berechnen

Muntazah Complex (Exit - 25)

Jebel Ali Village - Dubai (VAE)

Telefon: +971 4 8845001

E-Mail: info@skz-me.com

Route berechnen

Ul. Kwiatkowskiego 5a

52-407 Breslau, Poland

Telefon: +48 71 35 84 000

E-Mail: dopak@dopak.pl

Route berechnen

Ikitelli OSB Demirciler Sanayi Sitesi, E2 Blok No:420

34490 Başakşehir İstanbul | Turkey

Telefon: +902126718170

E-Mail: info@polmakplastik.com

Route berechnen

SKZ – Testing GmbH

Friedrich-Bergius-Ring 22

97076 Würzburg

Tel. +49 931 4104-0