Search standard for testing available at SKZ

Search standard for testing available at SKZ

We test according to common standards as well as individually and industry-specific – especially for automotive suppliers, the construction industry and for experts.

We test according to common standards as well as individually and industry-specific – especially for automotive suppliers, the construction industry and for experts.

Your experts for weathering tests

Weathering, UV resistance and more!

Test methods in the field of weathering and UV resistance simulate an outdoor climate with various combined stress factors, e.g. UV radiation/light, humidity, rain and heat under standardized laboratory conditions. These procedures allow considerable time savings in service life estimation, and reproducible test results are obtained.

With our highly qualified staff and by using our comprehensive equipment park with state-of-the-art testing machines, weathering tests can be carried out promptly according to almost all relevant norms and testing standards.

Main test methods

Das SKZ verfügt über mehrere Geräte mit Xenonbogenlampen (Xenotestgeräte). Diese stellen das vollständige Spektrum des Sonnenlichtes, d.h. vom kurzwelligen UV- bis zum langwelligen IR-Bereich mit hoher Genauigkeit nach. Außerdem können diese Geräte auch zahlreiche weitere Prüfparameter wie z. B. Lufttemperatur, Schwarzstandardtemperatur, Luftfeuchte und Beregnungszeit mit hoher Genauigkeit steuern und regeln.

Relevante Normen:

- DIN EN ISO 4892-1/-2, DIN EN 513, ISO 16474-2

SKZ has several rapid weathering devices with UV fluorescent lamps as the light source. These expose the samples only to the high-energy UV component of natural solar radiation. Due to this, these tests are mostly only used for materials whose spectral sensitivity is mainly in a wave range between 300 and 400 nm.

Relevant standards:

- DIN EN ISO 4892-1/-3, DIN EN 12224, ISO 16474-3

In this test in a Xenon test device, the test program and the test parameters are adapted to the testing of products such as window profiles and their components such as films, coatings and seals or sealants. Important evaluation criteria are color stability and mechanical properties. The test is used to assess the durability / service life of products in different climatic zones and is used in formulation development, product monitoring and product certification.

Relevant standards:

- EN 12608-1, EN 513, RAL-GZ 716, NEN 7034-2, SASO 2052, SASO 2053 (window profiles), ISO 11431, ISO 11617 (sealants)

This test is based on a test in a xenotest device, which, however, is specially equipped for certain tests in the automotive or paint industry. The Weather-Ometer available at SKZ also has a highly accurate sensor system for measuring surface temperatures of the samples during the weathering period.

Relevant standards:

- SAE J 2527 or SAE J 2412

For testing components used indoors, weathering equipment can be equipped with window glass filters which absorb part of the high-energy UV spectrum. Such tests are generally performed without water spraying and using only moderate air temperatures. Irradiation is usually followed by visual inspections and color and gloss measurements. In some cases, additional mechanical tests must be performed.

Relevant standards:

- e. g. according to DIN EN ISO 4892-2, procedure B or DIN EN ISO 4892-3, UVA-351

In this test specification, a xenotest device is used to simulate a dry, hot climate similar to a typical desert climate (e.g. Kalahari or Arizona). Such a test is frequently used for initial sample approval. Following weathering, visual inspections and color and gloss measurements are usually carried out; in individual cases, mechanical tests are also possible.

Relevant standards:

- PV 3929 „Kalahari Test“

This test specification uses a xenotest device to simulate a warm, humid climate similar to the climatic regions of Florida or southern France. Such a test is frequently used for initial sample approval. After weathering, visual inspections and color and gloss measurements are usually carried out; in individual cases, mechanical tests are also possible.

Relevant standards:

- PV 3930 „Florida Test“

This is a pure light exposure test, i.e. without water spraying. The test is mostly used for components of the vehicle interior (e.g. textile fabrics or small plastic or elastomer parts), which can be subjected to very high stress temperatures - up to 100 °C or more, depending on the installation position - especially in summer. The exposure is usually followed by visual inspections and color and gloss measurements.

Relevant standards:

- e.g. according to PV 1303

Using so-called flatbed devices with xenon radiation technology or sun simulators with metal halide lamps, even larger components and assemblies can be tested in their complete state. After completion of the test, either a test agreed with the client takes place or the test specimens are returned to the client for his own assessment.

Relevant standards:

- e.g. according to DIN EN ISO 4892-2 or DIN 75220

So far, little is known about the resistance of polymer materials to UV-C radiation, especially in long-term applications. In order to be able to draw conclusions from the exposure of materials to UV-C radiation on the degradation of surfaces and the remaining service life, the SKZ test laboratory is currently developing various test scenarios. The focus here is on UVC-254 lamps simulating the germicidal UV-C radiation used in sterilization equipment.

Relevant standards:

- DIN EN 60335-1 (VDE 0700-1)

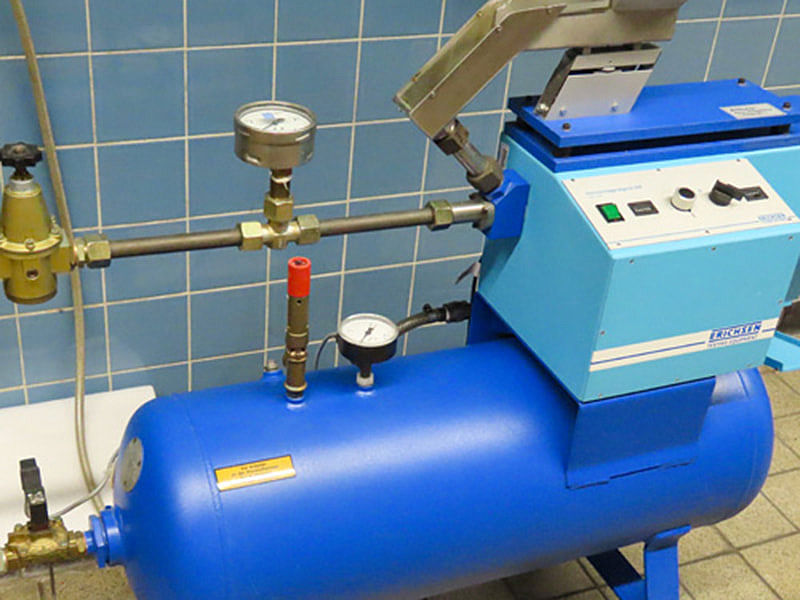

State-of-the-art equipment for best results and products

In our various laboratories and test rooms, we have a wide range of testing equipment for different weathering tests.

Additional test methods

These test methods are often used to detect or quantify any material change or damage due to weathering.

This method is used for the simple evaluation of changes in brightness, gloss and color. The evaluation is carried out according to DIN EN 20105-A02/03 by means of a grading system from 1 to 5 in direct comparison to a non-weathered specimen under standard lighting conditions.

This test determines the resistance of a specimen to an impact-like bending load applied at high speed. The test is usually performed in accordance with DIN EN ISO 179, generating a material parameter that can be used to quantify the brittleness of a material. In most cases, brittleness reacts very sensitively to weathering influences. Specimens that do not break or only partially break due to their toughness are notched before measurement.

Molecular degradation due to weathering can be detected by rheological measurements, primarily using MFR/MVR tests according to DIN EN ISO 1133-1/2. A near-surface assessment of material degradation can be made by viscosity measurements, e.g. according to DIN EN ISO 307 or DIN EN ISO 1628-1 to 5, or by gel permeation chromatography (GPC).

Colors and color changes can be quantified with precise measuring instruments, e.g. according to DIN 7724, DIN 53236-B. Depending on the application, different illumination sources (e.g. D65) and measuring geometries are used, e.g. d/8°, 45/0°, with/without gloss trap. The various colorimetric values can be clearly displayed, e.g. in the CIELab or Munsell system. The yellow value, e.g. according to ASTM E 313, can be used to display the yellowing.

Gloss measurements according to DIN EN ISO 2813 are frequently used for coated, painted, high-gloss or chrome-plated surfaces. The ratio between the incident light and the light reflected from the surface is determined at a fixed measuring angle. The unit of measurement used is GU (Gloss Unit).

Changes in surface structures can be evaluated microscopically. Typical anomalies are, for example, cracking, local discoloration or chalking. The examination is usually performed with reflected light microscopes. Scanning electron microscopy (SEM) enables an observation of very small surface anomalies and thus, early onset of material or product failure.

The steam jet test (e.g. according to PV 1503) has established itself in recent years as one of the most important adhesion test in the automotive sector. When performing the steam jet test, a painted sample is first scribed down to the substrate using a special tool (e.g. scribe according to Sikkens). The specimen is then subjected to a pressurized water jet under defined conditions. Depending on the adhesion of the coating, it is peeled off starting from the scribed edge.

This test determines the resistance of a film or a very thin test specimen to an abrupt tensile load applied at high speed. The test is usually carried out according to DIN EN ISO 8256, generating a material parameter that can be used to quantify the brittleness of a material. In most cases, brittleness reacts very sensitively to weathering influences.

Bending tests belong to the classical mechanical tests and can be carried out, for example, according to DIN EN ISO 178. A 3-point test is often used here, whereby the specimen is stressed by a test punch using a low loading speed. The measurement is usually carried out until the specimen breaks. The bending stress or bending force is recorded as a function of the deflection of the specimen.

Tensile tests belong to the classical mechanical tests and can be carried out, for example, according to DIN EN ISO 527. Standardized specimens with a defined cross-sectional area are uniformly and shock-free stretched to failure at a low deformation rate and a stress-strain diagram is recorded.

The cross-cut test (e.g. according to DIN EN ISO 2409) is a test method for estimating the resistance of a coating to separation from the surface of the plastic part. For this purpose, a special multi-cutter is used to cut a continuous grid into the coating up to the substrate. Cross-cutting tests are carried out both in the automotive sector and in the testing of laminated window profiles, for example.

This mechanical test can be used to determine the extent to which the adhesion of, for example, a laminating film to a PVC profile changes or deteriorates as a result of weathering. The peel strength can be determined, for example, according to DIN EN 17271.

When weathering complete components or assemblies, specific functional tests often have to be carried out in order to prove that they are not impaired by the influence of weathering. Of course, we also carry out such tests by agreement with you or return the weathered test specimens to you for your own tests or measurements.

Pebbles, grit and gravel are always lying on paths and roads. If they are thrown into the air at high speed, they can hit vehicles and damage their paintwork. How well a coating withstands such bombardment by a large number of small particles can be simulated with stone impact tests (e.g. according to DIN EN ISO 20567-1). The degree of damage is evaluated visually.

One year in a few days ...

Using numerous test methods, our specialists provide meaningful results on many questions relating to the weathering of plastics – quickly and reliably.

One year in a few days ...

Using numerous test methods, our specialists provide meaningful results on many questions relating to the weathering of plastics – quickly and reliably.