Search standard for testing available at SKZ

Search standard for testing available at SKZ

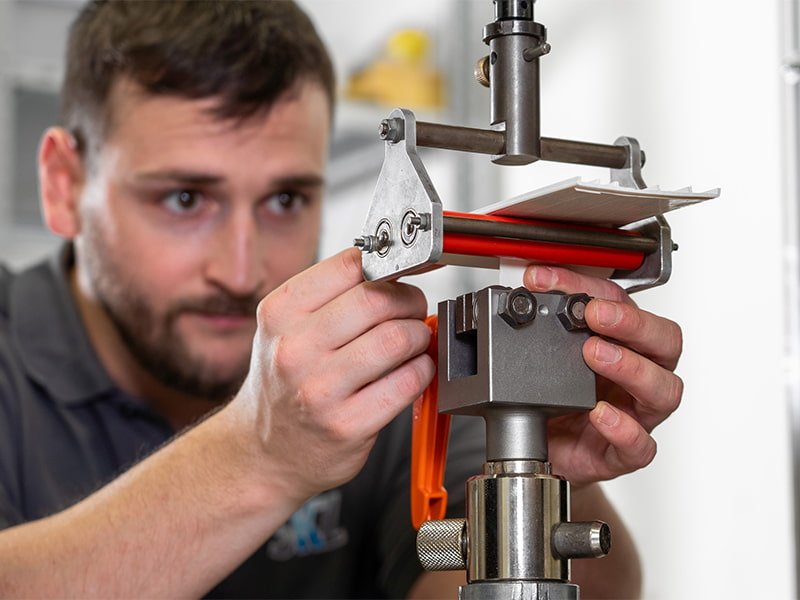

Testing of adhesives

Adhesives are tested to ensure their quality, safety, reliability and suitability for specific applications. Testing is essential in many industries and applications, as it ensures that adhesives meet the expected requirements and standards. An essential reason for testing adhesives is to ensure their adhesion and strength. Adhesive strength is one of the most important properties of an adhesive, and testing ensures that it bonds the desired materials securely and permanently under various conditions, such as stress, temperature or humidity.

Last but not least, adhesives are tested for their long-term durability, for example by means of aging or stress tests, which show how long an adhesive retains its properties under certain conditions. This is particularly important for applications that require a high level of durability. Overall, the testing of adhesives is an important step in ensuring performance, safety and suitability for the intended applications, thus ensuring customer satisfaction and regulatory compliance.

Typical types of adhesives for plastics

They are known for their fast curing and strong adhesion – ideal for applications that require high strength.

They are flexible and resistant to moisture and chemicals, making them ideal for applications that require flexibility and impact resistance.

Hot-melt or melt adhesives are adhesives that are applied by heating and then cooling quickly to form a strong bond.

They offer excellent strength and chemical resistance and are often used for structural applications.

They cure very quickly and provide strong adhesion to a wide variety of plastics.

We offer the following tests:

- DIN EN 1464

Adhesives – Determination of the peel resistance of bonds –

Roll peel test Tensile tests 3 - DIN EN 1465

Adhesives – Determination of the tensile shear strength of lap joints Tensile tests - DIN EN 14680

Adhesives for non-pressure thermoplastic piping systems –

specifications (here: sections 4, 5 and 6.2) - DIN EN 14814

Adhesives for pressure piping systems made of thermoplastic

materials for fluids - specifications (here: sections 4, 5 and 6.2) - DIN EN 28510-1

Adhesives - Peeling test for flexibly/rigidly bonded samples –

Part 1: 90° peel test - DIN EN ISO 11339

Adhesives – T-peel test for bonded joints with flexible adherends - DIN EN ISO 8510-2

Adhesives – Peel test for flex-rigid bonded samples –

Part 2: 180° peel test - DIN EN ISO 9311-3

Adhesives for thermoplastic piping systems –

Part 3: Test method for internal pressure strength