Search standard for testing available at SKZ

Search standard for testing available at SKZ

Microscopy

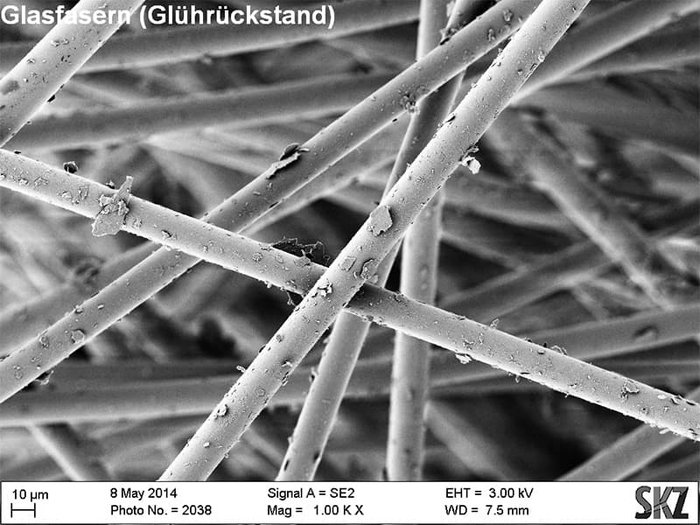

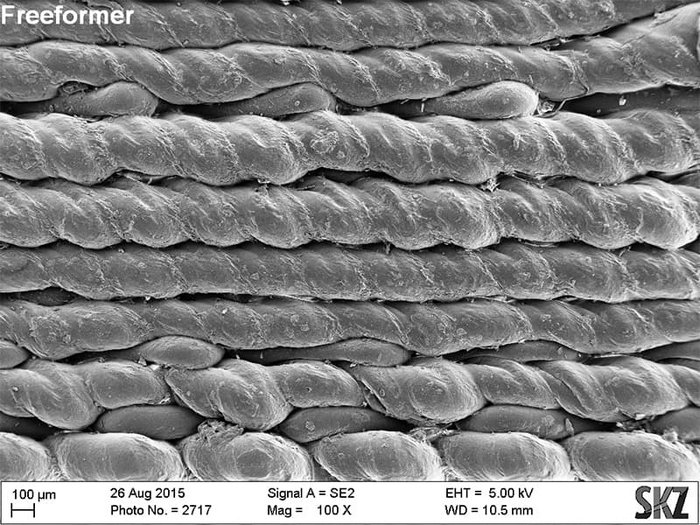

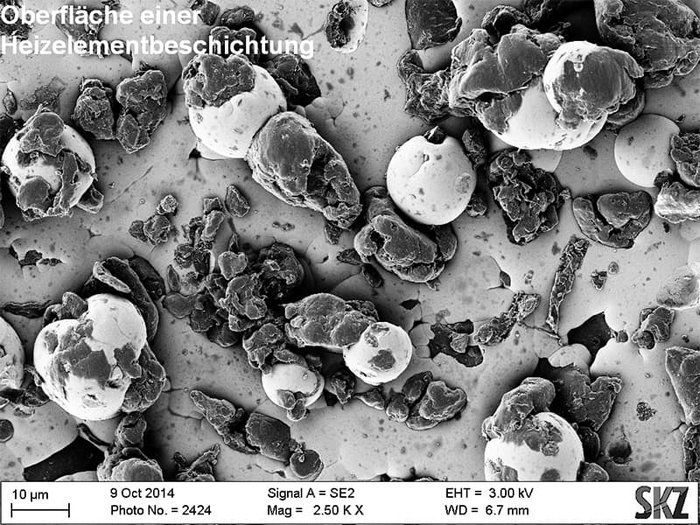

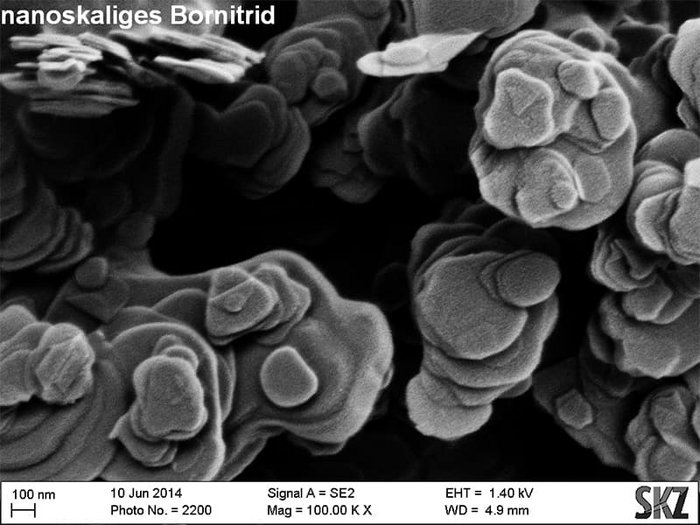

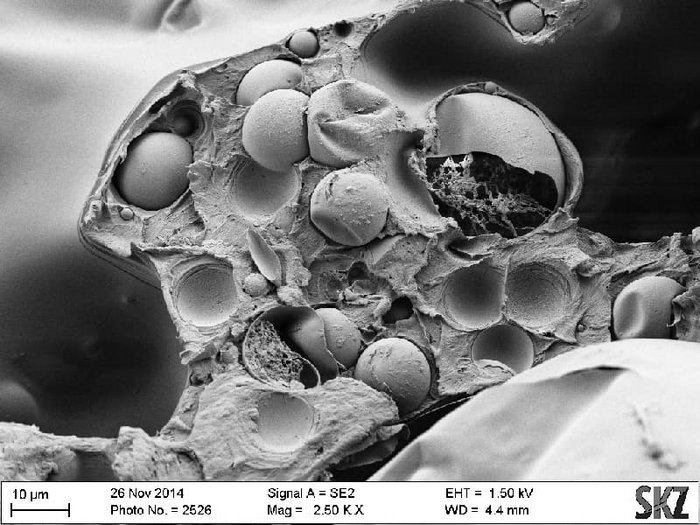

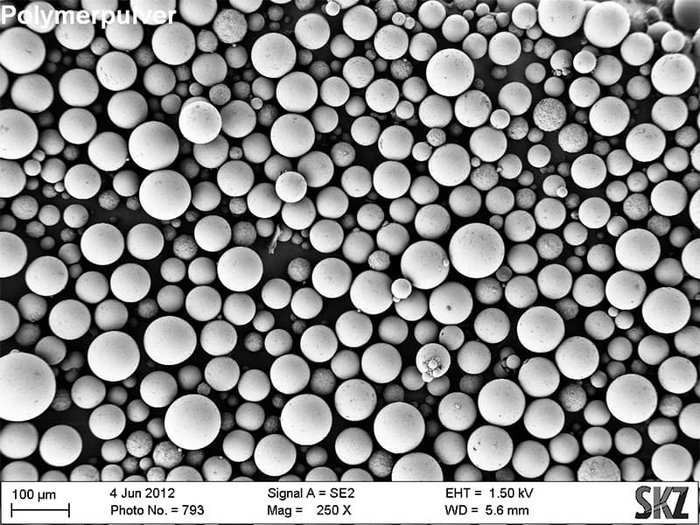

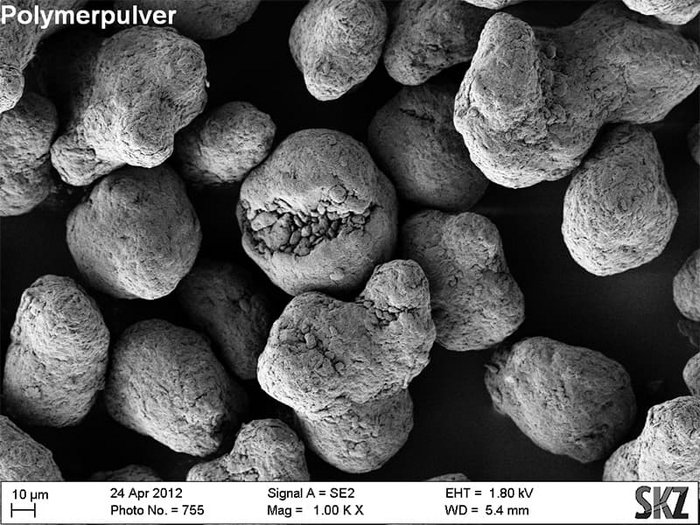

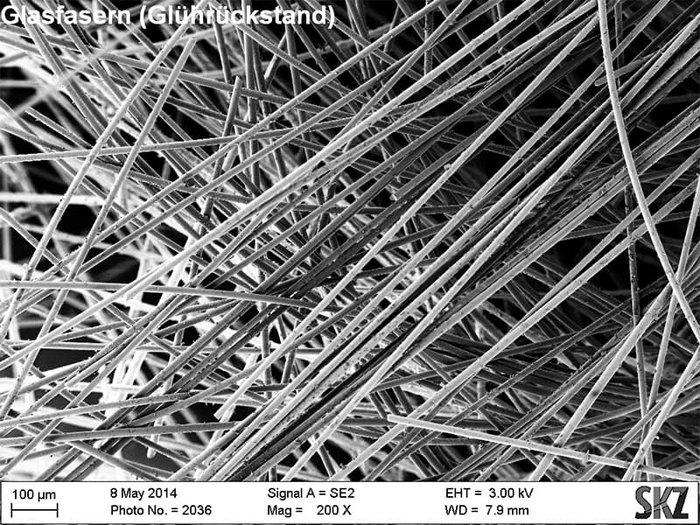

In plastics testing, microscopy plays a decisive role in the analysis and evaluation of material properties, as in most cases these are significantly influenced by the microstructure and surface structure. A wide variety of microscopic techniques are available in our laboratories, which can provide a wide range of information about a component, e.g. processing quality, ageing condition or degree of damage, as well as possible weak points or causes of damage.

Further details on this test method

In our test laboratory, different methods are used to prepare samples for microscopy.

- Direct sampling from test specimens, components or granulates

- Production of thin sections using microtomy

- Production of microsections by embedding, grinding and polishing

- Preparation of cryogenic fractures

- Production of cross-sections, e.g. for foil samples

- Incineration for filler analysis

Types of lighting

- Incident light

- Transmitted light

- Sidelight

- Segmentable ring light

Contrasting types

- Bright field

- Dark field

- Polarization

- Polarization with retardation plates

Detection types in scanning electron microscopy (SEM)

- Secondary electron detector (SE) for topography contrast

- Backscatter electron detector (BSE) for material contrast

- InLens detector for low-voltage operation

- VPSE detector for low-vacuum investigations

- EDX detector for elemental analysis

- Stereomicroscope: 5x to 63x magnification

- Classic light microscopes: 25x to 1,000x magnification

- Digital light microscopes: 20x to 1,000x magnification, motorized specimen stage, 3D display and automatic image stitching possible

- High-resolution field emission scanning electron microscope (FE-REM): up to 900,000x magnification, resolution < 5 nm, coupled with EDX detector for element analysis

- FTIR microscope

- Surface characterization

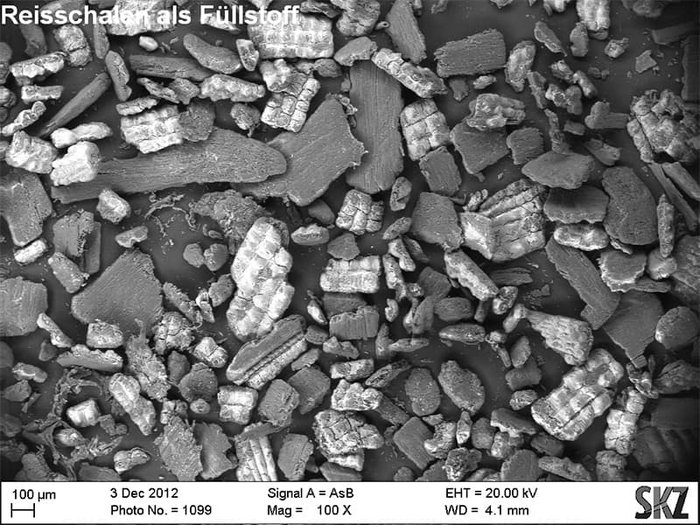

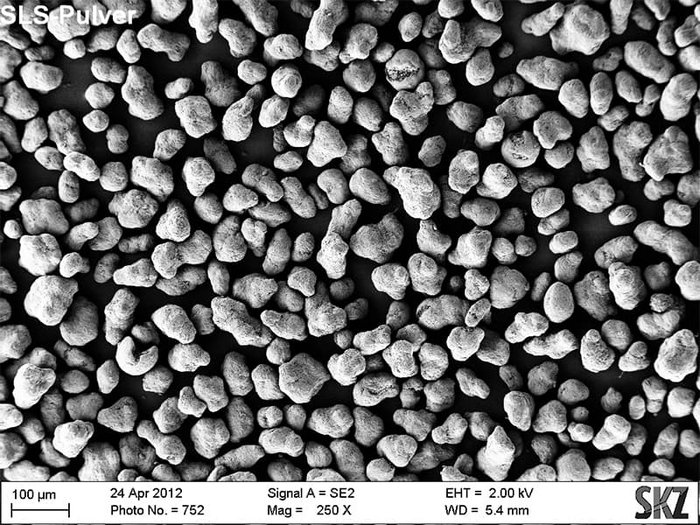

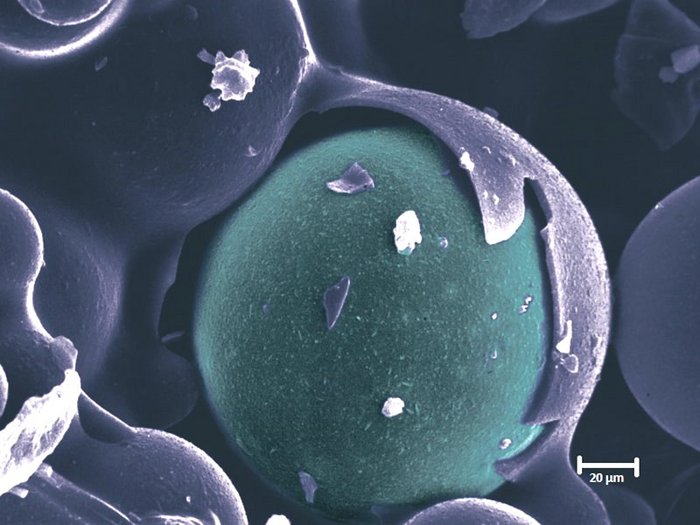

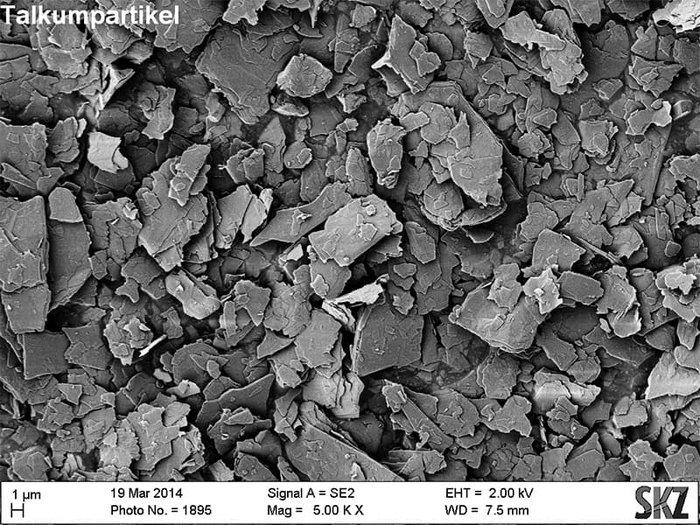

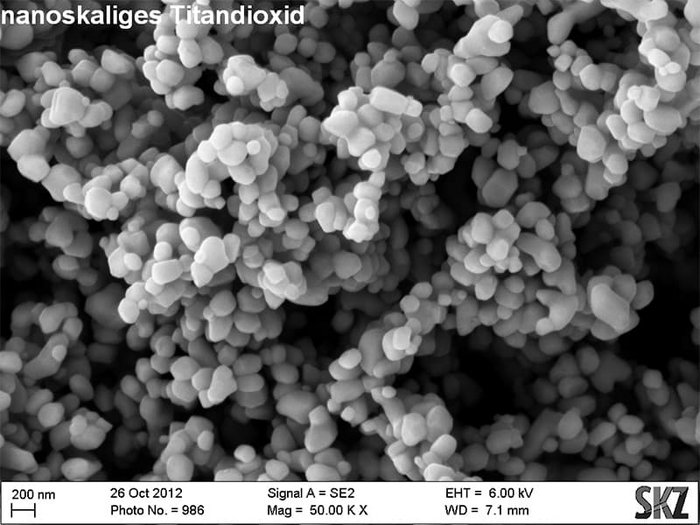

Surface analyses are particularly relevant when it comes to characterizing functional materials or high-quality visible parts, which are used in medical technology or the automotive industry, for example. - Microstructure analysis

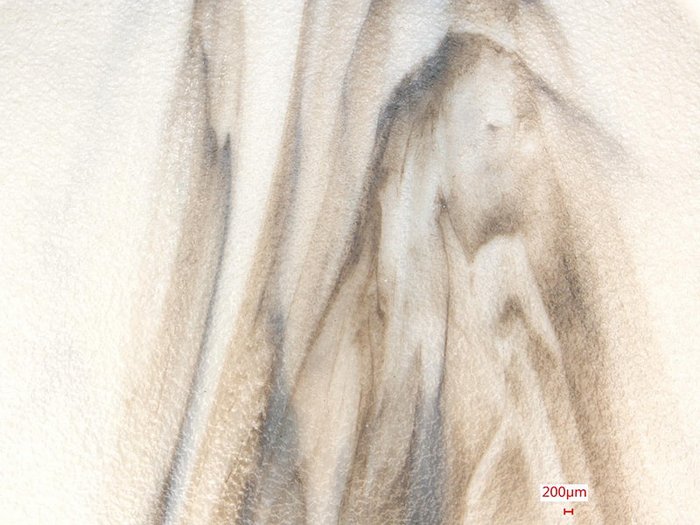

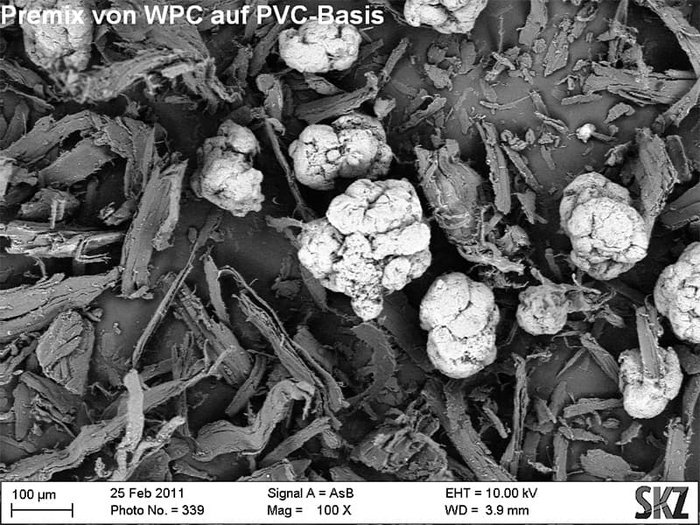

The microscopic examination of microstructures and/or filler size distributions is used for almost all types of plastic and enables the establishment of structure-property relationships. - Stress optics

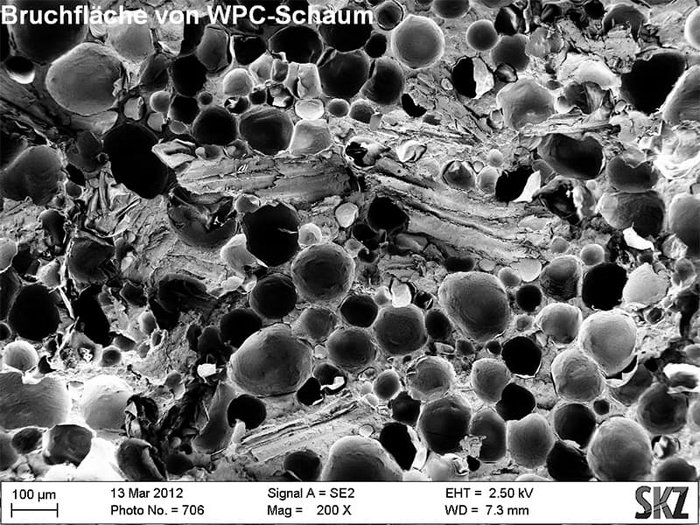

By using polarization filters, stress-optical examinations can be carried out which allow comparative statements to be made about the internal stress state of transparent plastic components. - Failure analysis

In the event of material failure or damage to plastic components, microscopy can be used to analyze fracture surfaces, cracks and damaged areas in order to determine possible causes of damage or identify weak points. This is crucial in order to develop suitable solutions and avoid future failures.

State-of-the-art equipment for the best results and products

In our various laboratories and test rooms, we have a wide range of testing equipment for different methods of plastics testing.

97076 Würzburg

Telefon: +49 931 4104-0

E-Mail: info@skz.de

Route berechnen

97082 Würzburg

Telefon: +49 931 4104-123

E-Mail: training@skz.de

Route berechnen

Köthener Str. 33a

06118 Halle (Saale)

Telefon: +49 345 53045-0

E-Mail: halle@skz.de

Route berechnen

Rauher Grund 9

72160 Horb am Neckar

Telefon: +49 7451 62457-0

E-Mail: horb@skz.de

Route berechnen

Woltorfer Str. 77, Halle G

31224 Peine

Telefon: +49 5171 48935

E-Mail: peine@skz.de

Route berechnen

Weißenbacher Str. 86

95100 Selb

Telefon: +49 9287 99880-0

E-Mail: ezd@skz.de

Route berechnen

Via Buonarotti 175

20900 Monza, Italy

Telefon: +39 039 281561

E-Mail: info@prochema.it

Route berechnen

Str. Iancu Jianu, nr. 26

500178 Braşov, Romania

Telefon: +40 268 412 559

E-Mail: office@plastics-bavaria.ro

Route berechnen

Muntazah Complex (Exit - 25)

Jebel Ali Village - Dubai (VAE)

Telefon: +971 4 8845001

E-Mail: info@skz-me.com

Route berechnen

Ul. Kwiatkowskiego 5a

52-407 Breslau, Poland

Telefon: +48 71 35 84 000

E-Mail: dopak@dopak.pl

Route berechnen

SKZ – Testing GmbH

Friedrich-Bergius-Ring 22

97076 Würzburg

Tel. +49 931 4104-0