Search standard for testing available at SKZ

Plastic films

The most important function of films is to protect products and materials in order to maintain or extend the shelf life or durability of the products inside. It is therefore necessary for films to undergo a wide range of tests to ensure their quality and performance for the intended application.

Films for photovoltaic systems

The testing of films (especially backsheets) for photovoltaic systems provides important test results for assessing the durability and reliability of solar modules. The main focus here is on the effects of high temperatures, temperature fluctuations, moisture and UV radiation. In order to comprehensively examine the resistance of the films to these influences, tests can be carried out in special environmental simulation systems. This ensures that the films meet the high requirements of the industry and make a decisive contribution to the performance and ultimately the optimum energy generation of PV systems.

Packaging films

These are made of a wide range of different plastics and are important packaging materials that help to better protect products. They ensure the integrity or freshness of food or have a collecting function for transportation. The most important film types in this area are multi-layer composite films, blown films, flat films, shrink and stretch films, and air cushion films.

Agricultural films

These are films used in agriculture and horticulture. They are used as ground cover for soil such as arable land and beds, for example, for crop advancement as mulch or asparagus films, or to cover greenhouses and tunnels in vegetable, fruit and flower growing. They are also used in the preparation of animal feed as silage films and tubes to cover feed silage and as stretch films for machine wrapping of bales of material for silage preparation.

Construction films

These are usually waterproof films used in the construction industry to protect construction sites, buildings and building materials from moisture, dirt and other damage. Depending on the exact application, different types of film are used, e.g. simple construction site covering films, barrier layer films for floor tiles or also vapor barrier or vapor retarder films, as well as underlay and roof lining membranes

Films for the automotive industry

Vehicle films have been growing in popularity for years. It is no longer just taxis, sports cars and premium vehicles that are wrapped with films. In addition to full wrapping, vehicle owners can also choose to wrap individual body parts or windows. Other films are used to protect particularly vulnerable areas such as the loading sill or the paintwork at the front and bottom.

Our committee work

- NA 054 Standards committee for plastics (FNK) NA 054-04-10 AA „Thermoplastic films for use in agriculture“

- Technical Committee (TC) „Films and netting“ at Deutsche Landwirtschaftsgesellschaft e.V. (DLG)

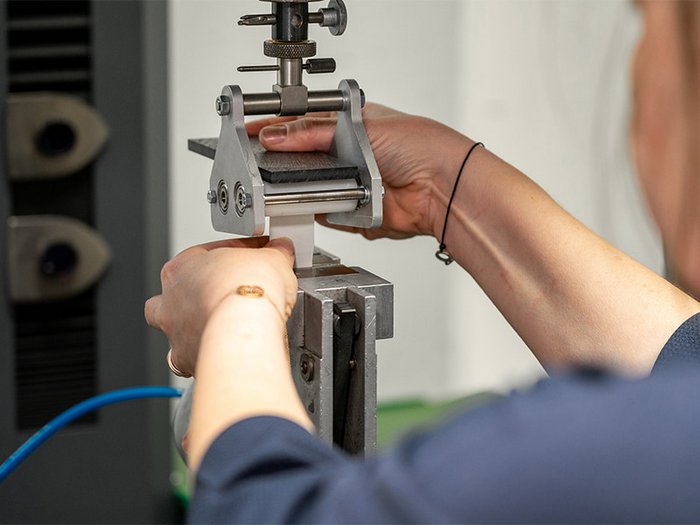

Testing of plastic films

Testing plastic films is crucial to ensure that they are suitable for their intended application and have the necessary mechanical, thermal, optical and chemical properties. This is for quality assurance, functionality, product safety and compliance with legal requirements.