Find projects

Component properties

Plastic products with best quality, lifelong

High-quality plastic products require the exact match of the component properties with the customer's expectations. These properties are unique for each component and result from the combination of factors like the material properties (mechanical, thermal, chemical, etc.), the product design, the processing and the application conditions (load type and duration, ambient media, etc.).

Component properties, such as the deformation and failure behavior under static or dynamic long-term loading, the aging resistance of the plastic under application conditions or processing-related influences such as residual stresses are very decisive factors for the quality and service life of plastic products. In order to optimize your products more efficiently, we want to determine the component properties more precisely, more quickly and more easily. The accelerated testing of the long-term and aging behavior of plastics is an important focus of our work, in order to be able to ensure the required service life of up to 100 years within the shortest possible time (days to a few months). Furthermore, we deal with process-structure-property relationships in order to be able to specifically optimize plastic products with regard to their property profiles. In addition to experimental methods for service life prediction, we also deal with simulative methods for predicting the deformation and failure behavior of plastic components (structural simulation).

Services

The mechanical behavior of plastics is very complex compared to classic metallic materials, as it is strongly dependent on temperature and time, among other factors. This becomes apparent, for example, in the form of creep and relaxation.

Testing of mechanical properties is carried out at SKZ in the form of both material and component tests. Tests on deformation and failure behavior under different types of stress (e.g. tension, compression, bending) can be carried out over a wide temperature range. Deformation and failure behavior is investigated in the form of both short-term and long-term tests. We also employ various accelerated testing concepts to determine long-term mechanical behavior.

Special topics are:

- Fatigue behavior of plastic products under cyclic long-term loading

- Creep and relaxation behavior under static long-term loading

- Accelerated determination of mechanical long-term behavior (e.g. Stepped Isothermal Method - SIM, Stepped Isostress Method - SSM)

- Deformation and failure behavior under different types of stress (e.g. tension, compression, bending)

- Temperature and processing dependent deformation behavior

- Non-contact measurement of local deformation fields (Aramis 3D system)

- Calculation and simulation of the deformation and failure behavior of plastic components

Contact:

Dr.-Ing. Kurt Engelsing | +49 931 4104-147 | k.engelsing@skz.de

Dr. Ruben Schlutter | +49 931 4104-4060 | r.schlutter@skz.de

Failure due to stress cracking is the most common failure cause with about 25 % of all failures for plastic components. Simultaneous exposure to stresses (external loads or residual stresses) and stress-cracking media can significantly reduce the failure times of plastic components.

In addition to evaluating stress cracking resistance using standardized test methods, we are dedicated to predicting failure times through accelerated test methods

Specific topics include:

- Accelerated test methods for slow crack growth in polyolefins

- Influence of different media and operating conditions or residual stress states on stress crack failure

- Quantitative determination of residual stresses

Contact:

Dr. rer. nat. Mirko Wenzel | +49 931 4104-347 | m.wenzel@skz.de

Britta Gerets | +49 931 4104-575 | b.gerets@skz.de

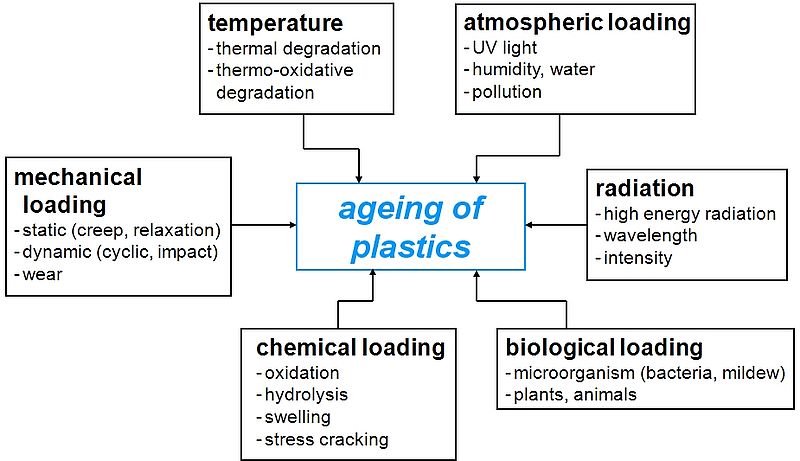

The aging of plastic products can be caused by a variety of influencing factors such as heat, UV radiation and media. In addition to the plastic used (polymer type and stabilization), aging strongly depends on the operating and environmental conditions of the plastic product. Appropriate accelerated test methods are necessary to accurately predict the expected service life within acceptable times.

At SKZ we investigate the aging behavior of various plastic parts under influencing factors like temperature, chemical agents and weathering. Besides the prediction of aging through accelerated testing, we focus on the development and application of suitable analytical techniques for the characterization of the aging state.

Special topics are:

- Thermo-oxidative aging (temperature, oxygen/oxidizing agents)

- Weathering behavior (UV radiation, temperature and humidity)

- Media resistance (e.g. hot water, cleaning agents, oils)

- Accelerated testing methods for predicting aging behavior

Contact:

Dr. rer. nat. Mirko Wenzel | +49 931 4104-347 | m.wenzel@skz.de

Britta Gerets | +49 931 4104-575 | b.gerets@skz.de

The properties of plastic components depend not only on the chemical/molecular structure of the polymer, but also on the morphology and residual stress state, which are processing-dependent.

Depending on the processing conditions, for example, different

- crystalline structures (degree of crystallinity, crystal modifications, superstructures),

- orientation states (molecular and fiber orientations leading to anisotropic properties)

- and residual stress states.

The effective determination of such effects and assessment of the resulting consequences for the component are investigated at SKZ with regard to component-specific issues. The aim here is to be able to control these effects in a targeted manner in order to avoid negative effects or even to gain new advantages.

Special topics are:

- Morphology investigations (amorphous or crystalline structures, molecular and fiber orientations, weld or flow lines, impurities, defects, etc.).

- Investigation of processing effects

- Quantitative determination of residual stresses

Contact:

Dr. rer. nat. Mirko Wenzel | +49 931 4104-347 | m.wenzel@skz.de

Britta Gerets | +49 931 4104-575 | b.gerets@skz.de

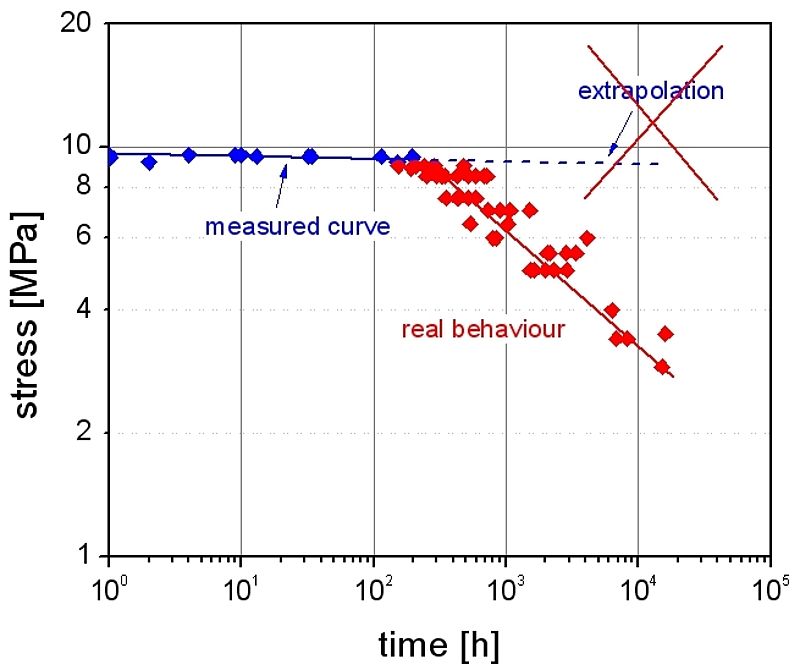

Ever higher demands are being placed on plastic components with regard to their service life, while at the same time the development times of new products are being reduced more and more. This often presents manufacturers and users of plastic components with the problem of having to make reliable predictions about the maximum service life of their products. In some cases, the required minimum service life can be 50 years or more (for example, plastic pipes or plastic sealing membranes). For this, even extrapolations based on long-term tests (typically in the range of several months) are no longer sufficient to derive reliable predictions by extrapolating to longer times.

For this reason, accelerated testing methods based on physico-chemical models are of great interest, as they allow reliable statements to be made about the long-term and aging behavior of plastics within a shorter period of time. In this context, it is of central importance that an acceleration of the test, e.g. via temperature increase, does not lead to a change in the failure mechanism, which would not occur at all in practice (under operating conditions).

The application and further development of methods for accelerated testing and service life prediction of plastic components is an important focus of our R&D activities.

We carry out investigations for you to evaluate the condition of aged plastic components and to predict the service life of plastic components in their new condition or after many years of use.

Special topics are:

- Condition assessment by means of innovative testing and analysis methods

- Accelerated test methods, which are adapted to the respective failure mechanism (e.g. creep or thermo-oxidative aging)

- Use of physical-chemical prediction models for service life estimation

- Simulation-based service life prediction at component level

Contact:

Dr. rer. nat. Mirko Wenzel | +49 931 4104-347 | m.wenzel@skz.de

Dr.-Ing. Kurt Engelsing | +49 931 4104-147 | k.engelsing@skz.de

Computer-aided methods such as the finite element method (FEM) allow efficient design and calculation of plastic and composite components. Appropriate modeling of material and component behavior can save time, material and costs at an early stage of development.

A meaningful simulation requires the best possible knowledge of the real material behavior, which is mainly dependent on the operating conditions (loads, temperature, humidity/media, etc.). Thanks to our extensive testing capabilities and decades of experience in the field of plastics technology, we are able to transfer all influencing factors (anisotropy, load type and duration, temperature, ambient conditions, etc.) to suitable simulation models. We would be pleased to support you with our expertise in your project.

We deal with:

- Thermoplastics, thermosets, elastomers

- Fiber-reinforced plastics (FRP)

- Material composites (hybrid components, e.g. plastic-metal)

- Isotropic and anisotropic as well as linear and non-linear material behavior

- Elasticity, plasticity, viscoelasticity, hyperelasticity

- Effect of environmental influences (temperature, humidity/media, etc.)

We offer:

- Deformation and strength analyses

- Calculation of long-term behavior and fatigue strength verification

- Calculation of mechanical and material connections

- Notch stress analyses

- Thermal analyses

- Determination of material properties

- Calibration and validation of material models

Contact:

Dr. Ruben Schlutter | +49 931 4104-4060 | r.schlutter@skz.de

Do you need support in the area of injection molding simulation including rheological and thermal design of injection molds?

Our experts from the injection molding department will be happy to help you.

Contact:

Thomas Zentgraf | +49 931 4104-232 | t.zentgraf@skz.de

As experts in the field of plastics technology, we strive to pass on the knowledge we have acquired over decades to our customers. From material development and manufacturing processes to the application of various testing and measuring methods - in our numerous practice-oriented training courses, you as a participant will acquire the necessary knowledge in dealing with plastics as a material. This begins with the selection of the right materials and compliance with production-oriented design rules, continues with the correct handling of equipment and machines for the manufacture and processing of plastic components and ends with the correct understanding of quality criteria and the associated use of testing and measuring tools.

Bringing together people from different areas of the company and from different sectors to exchange experiences and technical know-how is also a top priority for us, in addition to the pure transfer of knowledge. Our numerous specialist events provide the ideal venue for a free exchange of ideas. Renowned speakers from a wide range of industries and excellent technical presentations make the SKZ conference popular meeting places within the plastics industry.

State-of-the-art equipment for best results and products

A look inside our pilot plants and laboratories. On more than 1,000 square meters, we offer you service at the highest level. Challenge us. Together we will find a solution for your problem.

Technical equipment

At SKZ, we have numerous testing facilities for determining the properties of plastic parts in the form of material and component tests. In the SKZ testing laboratory, which is accredited according to DIN EN ISO/IEC 17025, we test according to more than 1,000 standards.

In addition to testing according to standards, we also develop innovative testing concepts for accelerated service life prediction (long-term and aging behavior) of your plastic components.

Special testing possibilities are: (excerpt)

- Determination of the fatigue behavior under cyclic long-term loading (determination of Woehler curves, hysteresis measuring method) in the temperature range -40°C to +150 °C

- Accelerated determination of long-term creep and relaxation behavior (creep apparatus with temperature chamber)

- Accelerated determination of stress crack resistance (media creep apparatus with temperatures up to 95°C)

- Quantitative determination of residual stresses (borehole method, PhotoStress)

- Locally resolved 3D deformation measurement on mechanically stressed components (gray value correlation, Aramis 3D)

- Laboratory weathering with determination of the surface temperature of the samples (Atlas Ci4000 Weather-Ometer S3T)

Please do not hesitate to contact us without obligation for suitable testing options for your individual requirements.