Search standard for testing available at SKZ

Search standard for testing available at SKZ

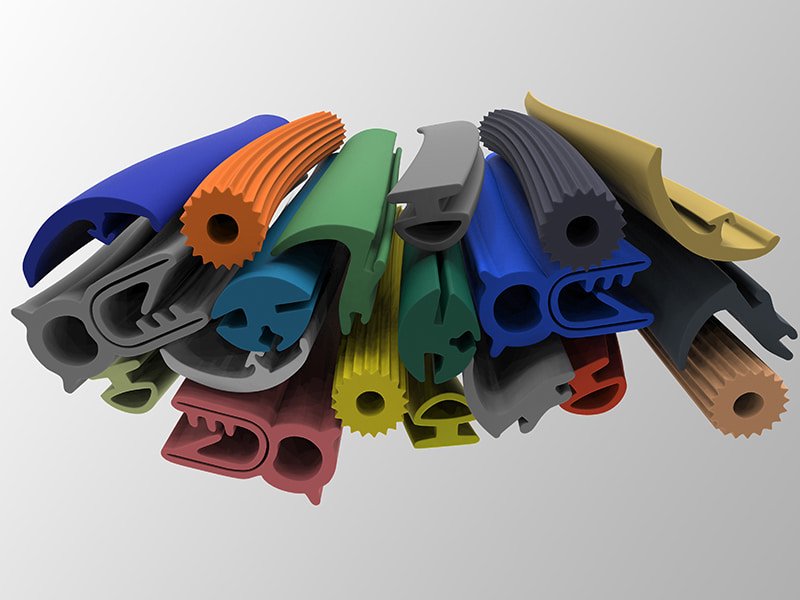

Testing of sealing profiles

Elastomerdichtungen werden in vielen Bereichen eingesetzt, um eine wirksame Abdichtung gegen Gase, Flüssigkeiten und Staub zu gewährleisten. Haupteinsatzgebiete sind Fenster- und Türdichtungen zur Wärme-, Schall-, Wind- und Wasserabdichtung, die Automobilindustrie für Tür- und Fensterdichtungen, Motordichtungen sowie Dichtungen in Fluidsystemen. In der Bauindustrie werden sie zur Abdichtung von Fassaden, Dächern, undichtem Mauerwerk und zur Schalldämmung eingesetzt. Im Maschinenbau werden Dichtungen aus Elastomeren eingesetzt, um Leckagen zu verhindern und Maschinen und Apparate zuverlässig abzudichten. In sensiblen Bereichen wie der Lebensmittel- und Pharmaindustrie werden die Elastomerdichtungsprofile aufgrund ihrer Beständigkeit gegenüber bestimmten Medien eingesetzt, um den hohen hygienischen Anforderungen gerecht zu werden.

Seals for windows

Modern windows with high insulation values offer numerous advantages, but these can only be exploited to the full if the associated window seals are intact. These fulfill several important functions, including increasing energy efficiency. An effective seal prevents cold air from entering from outside and warm air from escaping from the living spaces. Missing seals would lead to considerable heat loss.

The seals also protect against environmental influences such as pollen, fine dust and moisture. They help to prevent unwanted draughts and improve noise protection, which further enhances living comfort. In addition, the seals play a decisive role in the window's resistance to repeated opening and closing. They prevent material wear at the points of contact between the frame and sash.

Window seals also prevent the unimpeded entry of harmful environmental influences such as noise, dust, draughts and water.

Seals in manhole liners

Elastomers can be used in shaft chucks to fulfill various functions. Shaft chucks are used in boreholes to stabilize the borehole diameter, seal the borehole and facilitate drilling progress. Elastomers, also known as rubber seals or rubber compounds, are used in various places:

- Sealing functions: Elastomers are used as seals in well chucks to prevent fluids from entering or leaving the wellbore. These seals help to maintain the integrity of the wellbore and keep out unwanted fluids such as water or gas.

- Flexibility and adaptability: Elastomers are able to adapt to different borehole geometries due to their flexible nature. This is particularly important as boreholes are often shaped in complex ways. The elastomer seals ensure that the shaft lining is well sealed and adapts to the varying conditions in the borehole.

- Vibration protection: Elastomers can also help to absorb vibrations and shocks that may occur during the drilling process. This helps to extend the service life of the shaft lining and improve the stability of the borehole.

The choice of elastomer materials depends on the specific requirements and the conditions in the borehole.

Our work on committees

We carry out the following tests on sealing profiles

- RAL-GZ 716 Section B Materials and compact gaskets and gaskets made from them:

- B.5.2.1 Density (B)

- B.5.2.3 Hardness (B)

- B.5.2.6 Tensile test (B)

- B.5.2.7 Compression set (only according to DIN EN ISO 815-1) (B)

- B.5.3 Behavior after hot storage (B)

- B.5.4 Behavior after artificial weathering (B)

- Qplus Swiss Quality Guideline for drainage systems

Part 1: Seals (R 592 012-1) - DIN EN 681-1, -2 and -4: Elastomer gaskets - Material requirements

for pipe gaskets for water supply and drainage applications - DIN EN ISO 868 Plastics and hard rubber

Determination of indentation hardness with a durometer (Shore hardness) - DIN ISO 48-4 Elastomers or thermoplastic elastomers

Determination of hardness - Part 4: Indentation hardness by durometer method (Shore hardness) - DIN ISO 815 Elastomers or thermoplastic elastomers

Determination of compression set - Part 1: At ambient or elevated temperatures (ISO 815-1:2019) - DIN 7863-1 Elastomeric sealing profiles for windows and façades

Material requirements - Part 1: Non-cellular elastomeric sealing profiles for window and façade construction - DIN 7863-2:2019-12 Elastomeric sealing profiles for windows and façades

Technical delivery conditions - Part 2: Cellular elastomeric sealing profiles for window and façade construction - DIN 7863-3:2022-02 Elastomeric sealing profiles for windows and façades

Material requirements - Part 3: TPE sealing profiles in window construction - DIN 7863-4:2023-10 Elastomeric sealing profiles for windows and façades

Material requirements - Part 4: PVC-P sealing profiles in window construction - ISO 37 Rubber, vulcanized or thermoplastic

Determination of tensile stress-strain properties (Elastomers or thermoplastic elastomers - Determination of tensile properties)

Determination of tensile stress-strain properties) - DIN 53504 Testing of rubber and elastomers

Determination of tensile strength, tensile strength, elongation at break and stress values in the tensile test - DIN ISO 48-2 Elastomers or thermoplastic elastomers

Determination of hardness - Part 2: Hardness between 10 IRHD and 100 IRHDRubber, vulcanized or thermoplastic - Determination of hardness - Part 2: Hardness between 10 IRHD and 100 IRHD - DIN ISO 34-1 Elastomers or thermoplastic elastomers

Determination of tear propagation resistance - Part 1: Strip, angular and curved test specimens