Find projects

Additive manufacturing

Additive manufacturing (AM) has developed significantly in recent years and is establishing itself as another manufacturing process in the industrial environment. The developments show that additive manufacturing/3D printing continues to be an up-and-coming and rapidly evolving field that is used in almost all industries and offers a wide range of applications. The SKZ is helping to shape this development and is constantly expanding its offerings in the areas of services, research and training within a competence center for additive manufacturing, the Center for Additive Production (CAP) in Würzburg.

At the same time, the transfer of know-how to companies must keep pace with the rapid technical development. To this end, the range of services has been expanded and new training courses have been designed. This provides companies with a central, competent and independent point of contact. New materials, processes and applications are constantly entering the market. From consulting services, design for additive manufacturing, component production and testing to training courses and workshops, we support you in understanding and utilizing the complex aspects of additive manufacturing. The race for the profitable use of additive manufacturing technologies for series products is globally recognizable and Europe can and must fight vigorously and sustainably for a pioneering role.

Our services

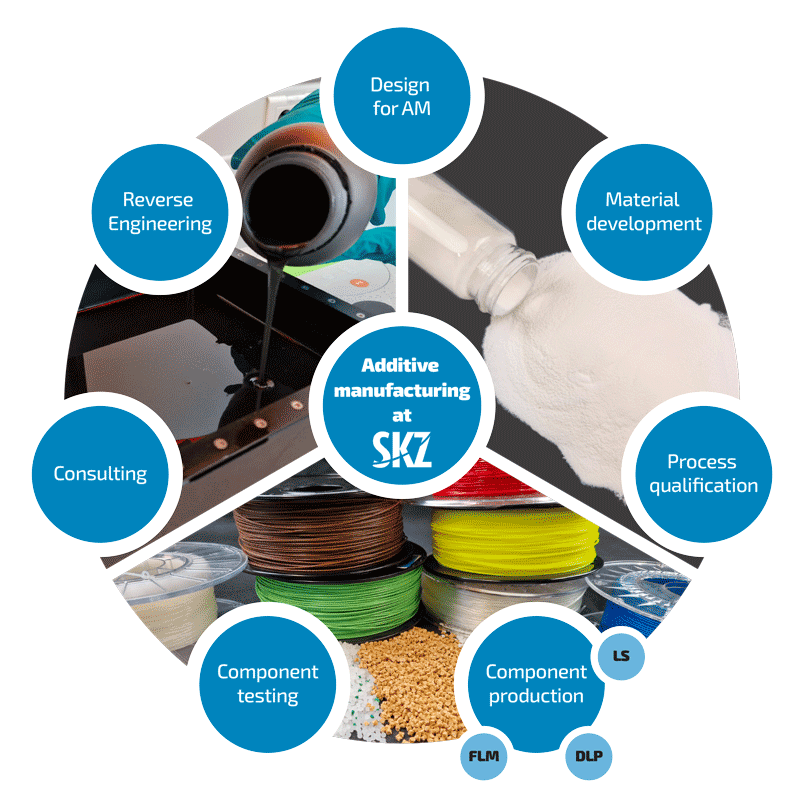

We are your enabler for innovative solutions in the field of additive manufacturing. Our experts offer customized services for material development, process qualification, reverse engineering, design for additive manufacturing (DfAM), component manufacturing and component testing as well as consulting.

Our focus is on developing targeted and application-oriented solutions for your project. With a wide range of software, materials, machine technology and expertise, we are at your side to help you realize your projects.

Whether prototype development, the production of complex components or the optimization of existing designs - we support you along the entire process chain. We offer you innovative solutions to meet your requirements and turn your visions into reality.

Our services are characterized by the highest quality, reliability and individual advice. As a pioneer, we are proud to be part of the success story of numerous additively manufactured products and to be able to support the development of new manufacturing technologies.

We would also be happy to make your project a success!

We look forward to achieving your production goals together and realizing your project ideas.

Our services at a glance

In order to exploit the full potential of additive manufacturing, the production-related restrictions and degrees of freedom must already be incorporated into the design of components during the construction phase. The right combination of modeling approach or strategy and the software used is essential.

Our experts are on hand to assist you and support you with various issues:

- New design and redesign for additive manufacturing

- Design of operating equipment (devices, tools and fixtures)

- Creating algorithms for simple variant design

- Texturing of components

- Creation of 3D lattice structures

- Design of bionic structures

- Generative design

- 3D scanning & reverse engineering

- Design of gripper systems (e.g. for injection molding)

- Design of orthoses and prostheses

To ensure that you reliably achieve the desired result, we support you in the design of your components - from the idea to the finished part.

Contact:

Kevin Popp | +49 931 4104-643 | k.popp@skz.de

SKZ focuses on reverse engineering and has various scanning solutions, both hand-held and stationary. Hand-held scanners are used in the field of medical technology, for example, to digitize implants or prostheses and adapt them to the individual needs of patients. Stationary scanners are used for quality assurance and the measurement of components, for example.

In combination with a variety of CAD tools and additive manufacturing systems, the SKZ is ideally positioned to handle any application. The reverse engineering experts can digitize components and convert them into a CAD model in the shortest possible time. This allows prototypes to be developed or spare parts to be manufactured, for example. The combination of 3D scanners and additive manufacturing systems enables projects to be implemented quickly and precisely. The SKZ is therefore an ideal point of contact for all projects.

Contact:

Kevin Popp | +49 931 4104-643 | k.popp@skz.de

The right materials form the basis for outstanding products manufactured using additive manufacturing. Together with partners, we are continuously developing new materials to push the boundaries of what is possible in additive manufacturing. Our dedicated team works to identify and develop materials that meet the specific requirements of different applications.

The state-of-the-art SKZ Technical Center is working on the development of new materials for laser-sintering (LS) (powder), fused layer modeling (FLM) (filament and granulate), as well as the resin-based processes digital light processing (DLP) and stereolithography (SLA). Material development in the resin area focuses in particular on the precise adjustment of the chemical composition and the targeted modification of viscosity, reactivity and curing behavior. This results in high-performance materials that guarantee high resolution and mechanical properties as well as consistent long-term performance.

Material development in additive manufacturing enables us to optimize material properties in order to improve functionality, strength, precision and surfaces. Customized materials open up new possibilities for applications and the production of high-quality components.

Contact:

Adrian Beetz

+49 931 4104-642 | a.beetz@skz.de

The production of test specimens according to various standards and special test specimens is part of our numerous customer and R&D activities. Furthermore, we offer the production of specimens designed specifically for the customer and their application.

Possible test specimens

- Specimens for tensile, bending, impact tests

- Puncture test specimens

- Fire test specimens

- Multi-material test specimens

- Test specimens for assessing colorability

- Test specimens for the overmolding of inserts

- Plates with different dimensions, thicknesses and surfaces

- Individual test specimens or plates

Contact:

Irena Heuzeroth | +49 931 4104-658 | i.heuzeroth@skz.de

Precise process analysis forms the foundation for high-quality components. The team places great emphasis on understanding every step of the additive manufacturing process to make it faster, more efficient and more reliable. We examine and evaluate the material properties, manufacturing parameters, machine performance and the quality of the additively manufactured components. Through systematic analysis, we identify potential areas for improvement and ensure that our processes work reliably. The SKZ also offers the integration and, if necessary, individual adaptation of non-destructive testing methods for monitoring printing processes and assessing the final component quality. In this way, you can detect defects such as a lack of layer adhesion or changes in geometry due to distortion at an early stage.

We also use state-of-the-art tools and technologies to monitor and control our manufacturing processes. This continuous analysis enables us to react immediately to challenges in order to ensure consistent quality and performance.

Contact:

Manfred Popp

+49 931 4104-200 | m.popp@skz.de

The filament is the backbone of every successfully additively manufactured component. At SKZ, we place particular emphasis on the production of high-quality filaments, which form the basis for precise and reliable results. For the production of filaments for additive manufacturing, the SKZ has two wire extrusion lines with a temperature-controlled water cooling section, as well as a desktop system for rapid trials. Filament diameter and ovality are monitored online using a three-axis laser measuring head.

Our production facilities are designed to produce filaments with exact diameters and uniform material properties. Our dedicated team of experts is constantly working to develop new material blends and optimize production processes.

Contact:

Patrick Limbach | +49 931 4104-473 | p.limbach@skz.de

Material qualification is a crucial step to ensure that the selected materials meet the requirements of your projects. We ensure that our customers have the opportunity to test materials before the actual manufacturing process to validate compatibility, strength, surface finish and other important parameters. Each additive manufacturing process has different material requirements. These include mass throughput, shrinkage, warpage, application and cooling behavior. In addition to the behavior in the process itself, pre- and post-processing is another important factor.

Our aim is to offer customized solutions that fully meet your requirements. Thanks to our extensive know-how, we can help you find the right choice of material for your specific applications.

Contact:

Manfred Popp | +49 931 4104-200 | m.popp@skz.de

Additively manufactured components are used in many areas. From samples and prototypes to production aids and operating resources through to components for series applications. We provide you with comprehensive support in the production of high-quality components using additive manufacturing processes. With our modern plant and equipment, we offer you the opportunity to cover a wide range of materials and applications.

From the initial idea to design and production, we support you with state-of-the-art technology and our expertise. Whether prototypes, small series or complex geometries - we offer customized solutions that are precisely tailored to your requirements. Together, we realize your visions precisely and efficiently.

Contact:

Kevin Popp | +49 931 4104-643 | k.popp@skz.de

As experts in the field of plastics technology, we strive to pass on the knowledge we have acquired over decades to our customers. From material development and manufacturing processes to the application of various testing and measuring methods - in our numerous practice-oriented courses and conferences, you as a participant will acquire the necessary knowledge in dealing with the material plastic. This begins with the selection of the right materials and compliance with production-oriented design rules, extends to the correct handling of equipment and machines for the production and processing of plastic components and ends with the correct understanding of quality criteria and the associated use of testing and measuring tools.

In the dynamic world of additive manufacturing, training and networking are essential to meet the demands of a constantly evolving technology. We offer first-class training programs to help you deepen your knowledge of the latest technologies. Our training, workshops and courses are led by industry experts who are eager to share their knowledge and experience.

In addition to further training, networking is a crucial component for success in additive manufacturing. We actively promote the exchange of ideas and experience between experts, customers and partners. Through our network, we offer you the opportunity to make valuable contacts and benefit from the diversity of expertise.

State-of-the-art equipment for best results and products

A look inside our technical center. On more than 1,000 square meters, we offer you service at the highest level. Challenge us. Together we will find a solution for your problem.

Technical equipment

FLM: Fused Layer Modeling

Fused Layer Modeling (FFF) is an additive process in which a supplied plastic wire (filament) is melted in a nozzle head. The emerging thin strand of melt is then used to build up the contour and filling of the desired geometry layer by layer. By using a removable support material in the area of overhangs, complex geometries with cavities, internal structures and large wall thickness variations are also possible.

The process is characterized by the following advantages:

- Very wide range of materials possible

- Multi-component parts possible

- Simple production of partially filled internal structures for lightweight construction

- Low-cost plant technology

TripleF

SKZ custom-built - max. build volume: 450 x 300 x 320 mm,

max. 3 print heads, max. nozzle temperature: 395 °C,

heatable build platform up to approx. 220 °C, heatable build area up to approx. 220 °C

TripleF mini

SKZ custom-built - max. build volume: 300 x 200 x 260 mm,

double print head for 2 filaments, max. nozzle temperature 395 °C,

heatable build platform up to 150 °C, heatable build space up to 85 °C

TripleF solid

SKZ custom-built - max. build volume 200 x 200 x 340 mm, single printhead,

max. nozzle temperature 290 °C, heatable build platform up to 150 °C

Prusa i3 MK2 and MK3

Prusa Research - max. build volume 250 x 210 x 210 mm,

single print head, additional extension to 4K printing available,

max. nozzle temperature 290 °C, heatable build platform up to 120 °C

Bambu Lab X1-Carbon with AMS

Closed installation space 256 × 256 × 256 mm

Passively heatable up to 60 °C, nozzle temperature up to 300 °C

Print bed temperature up to 110 °C

Up to 4 materials can be processed.

Apium P400

Max. build volume 400x300x300, IDEX system, max. nozzle temperature 540 °C, heatable build platform up to 200 °C, integrated dryer, specialized for high-performance thermoplastics (PEEK, PSU, PEI, Ultem)

SKZ Self-made pellet extruder

Processing of original material in various forms (granulate, powder). Possibility to process very soft or highly filled materials.

Contact:

Anne Gruska | +49 931 4104-378 | a.gruska@skz.de

Manfred Popp | +49 931 4104-200 | m.popp@skz.de

CFF: Continuous Filament Fabrication

The CFF process is basically based on the principle of the FLM process. The print head has two different nozzles. One nozzle deposits the melted filament as an "outer shell" as well as the inner matrix. The second nozzle is used to incorporate reinforcing fibers (possible fiber types: carbon, Kevlar, glass fibers). The fibers wetted with plastic are heated by the nozzle and applied to the previous layer. Shortly before reaching the end of the web, the integrated cutting unit cuts off the fiber. For stiff and strong components, not only the fibers but also the filling strategy can be decisive.

The process is characterized by the following advantages:

- resinless system

- Continuous fibers can be processed

MarkTwo Markforged

Printing of continuous fibers, max. build volume 320 x 132 x 154 mm

Freeformer: APF (ARBURG Plastic Freeforming)

The ARBURG Plastic Freeforming is a new additive manufacturing process and was first presented by the family-owned company ARBURG GmbH + Co KG at the K trade fair in 2013. The Freeformer processes standard pellets which get plasticized by a screw with three individual heating zones comparable to the IM process, and produces parts by building up tiny, contiguous droplets layer by layer. The discharge units, two nozzle shutters timed with piezo technology, remain stationary while the component carrier moves.

AKF (Arburg)

Build temperature: 50-120 °C; mass processing temperature: max. 350 °C,

maximum part size 1-component (x, y, z): 189 x 134 x 230 mm, maximum part size 2-component (x, y, z): 154 x 134 x 230 mm

3Devo

Processing temperatures up to 450 °C, throughput: up to 1 kg/h,

Extruder screw replaceable and nitride cured for abrasive materials, mixing zone for addition of additives.

Contact:

Irena Heuzeroth | +49 931 4104-658 | i.heuzeroth@skz.de

TripleF

TripleF mini

TripleF solid

Laser sintering (LS) technology, which has been used for the production of prototypes for many years, is increasingly finding its way into the industrial production of individual parts and small series. Innovative components such as removal grippers or prostheses can be implemented with a high degree of functional integration thanks to the many design degrees of freedom.

The process is characterized by the following advantages:

- No support structures necessary

- Very low anisotropy of the properties depending on the direction of construction

- High detail resolution

- Relatively fast manufacturing process

SLS Formiga P110

EOS GmbH - no support structures necessary, max. build volume 200 x 250 x 330 mm, laser type CO2, 30 W

SLS Weirather WLS3232Weirather GmbH - no supporting structures necessary, max. construction volume 320x320x380 mm, freely parameterizable, high installation space temperature (processing of demanding materials) Laser type CO2, 100 W

Semi-automated blast cabinet AMSolutions S1

AMSolutions – flexible, semi-automated blast cabinet for efficient powder removal and surface finishing. Use of various blasting media

Contact:

Kevin Popp | +49 931 4104-643 | k.popp@skz.de

DLP: Digital Light Processing

The DLP process (Digital Light Processing) is an additive process that uses a special resin (photopolymer) that cures under UV light. In contrast to the SLA process, exposure is by means of a DLP projector.

The process is characterized by the following advantages:

- Prints with very high, detailed resolution.

- Faster printing compared to SLA, since a layer is exposed and cross-linked as a whole

- Complex structures possible

- Transparent components possible

Digital Light Processing: Perfactory 3 DSP

max. build space of 140 x 105 x 230 mm, liquid plastic (photopolymer) exposed with UV via a DLP projector

Digital Light Processing: Uniontech Pi 200

max. installation space of 192x 108 x 200 mm, liquid plastic (photopolymer) exposed via a DLP projector with UV, 50 µm pixel size

Digital Light Processing: Uniontech EvoDent S110

max. installation space of 111 x 85 x 62 mm, liquid plastic (photopolymer) exposed via a DLP projector with UV, 58 µm pixel size

Contact:

Adrian Beetz | +49 931 4104-642 | a.beetz@skz.de

SLA: Stereolithography

SLA (stereolithography) technology is considered the first 3D printing process. Using a UV laser, the special resin (photopolymer) is cured layer by layer. All workpieces created with stereolithography undergo several finishing steps after successful printing: Intensive cleaning of the workpiece, removal of support structures, post-curing under UV light, mechanical post-treatment if necessary (grinding, blasting).

The process is characterized by the following advantages:

- Prints with high, detailed resolution

- Complex structures possible

- Transparent components possible

- No rectangular voxels as with DLP due to point laser, thus smooth edges are possible as well as no gradations in the vertical visible

Low Force Stereolithography: Formlabs Form 3

max. space of 145 x 145 x 185 mm, liquid plastic (photopolymer) exposed with a UV laser

Masked Stereolithography: Anycubic Photon S

max. build envelope of 115 x 65 x 165 mm, liquid plastic (photopolymer) exposed with UV via an LCD display

Analytics in the field of additive manufacturing

- Tensile test according to DIN EN ISO 527

- Three-point bending test according to DIN EN ISO 178

- Peel test according to VDI 2019

- Special test rigs: film hinges, determination of bond adhesion

Contact:

Irena Heuzeroth | +49 931 4104-658 | i.heuzeroth@skz.de

- Infrared camera with special filter for monitoring the laser-based melting process in the SLS process

- Camera systems mounted on print heads (FDM/ FLM/ FFF) for monitoring the deposition of the melt strand

- Measuring device for determining the feed force of the filament, from which the melt pressure in the nozzle can be derived

Contact:

Manfred Popp | +49 931 4104-200 | m.popp@skz.de

At SKZ, the particle properties of various materials can be determined using dynamic light scattering, laser diffraction, dynamic image analysis and sieving methods (measurable range: from 1 nm to 3500 µm depending on the test method). Depending on the application, materials that can be analyzed include emulsions, suspensions, powders (plastics, metals, foodstuffs, pharmaceuticals), granulates and small pellets, fillers (chalk, talc, glass beads), but also fine fibers (wood, glass and carbon fibers) and nanoparticles.

Results of the test method:

- Particle size and size distribution (distribution curve, Dx values, fraction percentages).

- Particle shape (including sphericity, length/width ratio)

Contact:

Patrick Limbach | +49 0931 4104-473 | p.limbach@skz.de

Bulk density and flowability are important parameters for the conveying and metering behavior of granules and powders. Especially in the production of compounds and components, these values are of great importance for production control.

Relevant standards (excerpt): DIN EN ISO 60 (bulk density), DIN EN ISO 6186 (pourability)

Contact:

Patrick Limbach | +49 0931 4104-473 | p.limbach@skz.de

By means of DSC (dynamic differential calorimetry) or hot stage microscope (temperature range from -196 to 600 °C)

Contact:

Patrick Limbach | +49 0931 4104-473 | p.limbach@skz.de