Search standard for testing available at SKZ

Search standard for testing available at SKZ

Ageing tests for plastics

Durability and quality assurance in various industries

Ageing tests are essential to ensure the durability and stability of plastics in a wide range of applications. In the automotive industry, they ensure the durability of bumpers and interior trim.

In the construction industry, they protect window frames and seals from environmental influences. The electronics industry relies on these tests to maintain the insulating properties of plastic components, while the packaging industry uses tests to ensure the strength of plastic packaging over the entire storage period. In medical technology, ageing tests ensure that plastics in devices and implants meet the highest quality and safety standards.

Our specialized test methods specifically simulate environmental factors such as UV radiation, temperature stress and chemical influences in order to detect potential material weaknesses such as cracking, colour changes or embrittlement at an early stage. Accelerated test methods provide manufacturers with fast and reliable results that give them a decisive advantage in product development

Further details on the test method

- General chemical resistance test, also at temperature, e.g. according to DIN EN ISO 175 or DIN EN 1847

- Autoclave test in water up to 130 °C

- High-pressure autoclave test up to 100 °C and 50 bar oxygen overpressure, e.g. in accordance with DIN EN ISO 13438

- Cold storage down to -60 °C, e.g. in accordance with DIN EN 495-5

- Climate change test, also in accordance with automotive regulations such as PV 1200

- Constant climate storage, e.g. in accordance with RAL GZ 716

- Salt spray test, e.g. in accordance with DIN EN ISO 9227

- Stress crack testing (ESC), e.g. bending strip test according to DIN EN ISO 22088-1 and DIN EN ISO 22088-3

- Stress corrosion cracking test (ESC) using FNCT in accordance with ISO 16770

- Thermal cycling test

- Heat ageing, hot storage or oven ageing up to 300 °C, e.g. in accordance with DIN EN 14575 or DIN EN ISO 13438

- Root strength test according to FLL guideline or DIN EN 13948

- Creep rupture test according to DIN EN ISO 1167 and DIN EN ISO 9080

The choice of specimen geometry depends heavily on the intended application of the plastics, as different products are subject to different requirements and loads. The test method also has an influence on the required geometry. For example, the following are used

- Sheets and films

- Tubes or rods

- Injection molded parts

You can find further interesting details on this and other topics in our whitepaper collection, which you can request free of charge.

- Modern chemical laboratory for the safe handling of hazardous substances

- 25 high-pressure autoclaves (up to 50 bar)

- 10 laboratory autoclaves (up to 4 bar)

- Over 700 pressure stations for pipe testing (up to 200 bar)

- Over 30 stations for temperature change tests on pipes (Ø 6 mm to 315 mm)

- 50 heating ovens

- 5 FNCT basins with a total of 54 measuring stations

- Several cold chambers

- Various climate change chambers

- Salt spray chamber with a sample holding area of up to 1.4 m x 0.5 m

Products tested so far

- Geosynthetics

- Yarns

- Geomembranes

- Pipes

- Nonwovens

- Sheets

- Woven tapes

- Components

These products consist mainly of polyolefins, such as polyethylene (PE) and polypropylene (PP). However, other materials such as polyvinyl alcohol (PVA) and ethylene-propylene-diene rubber (EPDM) have also been subjected to accelerated ageing.

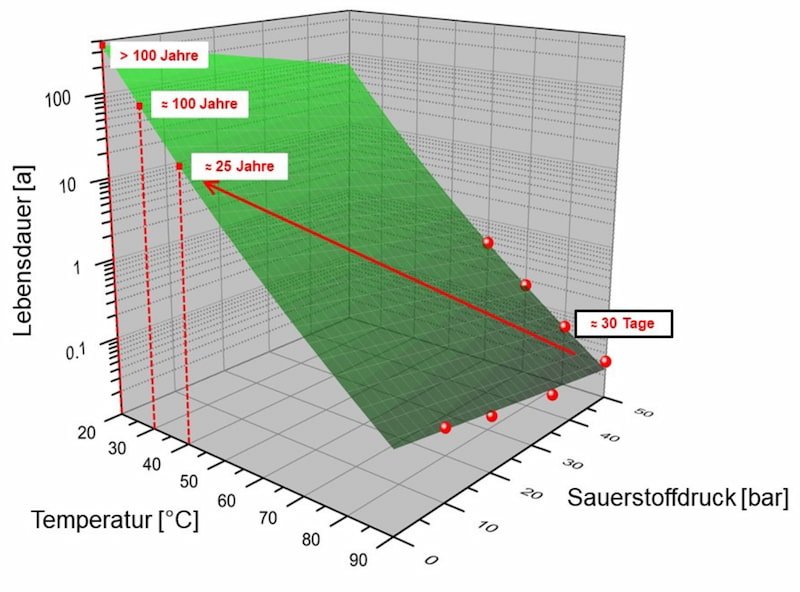

3D extrapolation for estimating the service life of plastic samples based on high-pressure autoclave tests at elevated temperature and increased oxygen pressure (Graphic: SKZ)

97076 Würzburg

Telefon: +49 931 4104-0

E-Mail: info@skz.de

Route berechnen

97082 Würzburg

Telefon: +49 931 4104-123

E-Mail: training@skz.de

Route berechnen

Köthener Str. 33a

06118 Halle (Saale)

Telefon: +49 345 53045-0

E-Mail: halle@skz.de

Route berechnen

Rauher Grund 9

72160 Horb am Neckar

Telefon: +49 7451 62457-0

E-Mail: horb@skz.de

Route berechnen

Woltorfer Str. 77, Halle G

31224 Peine

Telefon: +49 5171 48935

E-Mail: peine@skz.de

Route berechnen

Weißenbacher Str. 86

95100 Selb

Telefon: +49 9287 99880-0

E-Mail: ezd@skz.de

Route berechnen

Via Buonarotti 175

20900 Monza, Italy

Telefon: +39 039 281561

E-Mail: info@prochema.it

Route berechnen

Str. Iancu Jianu, nr. 26

500178 Braşov, Romania

Telefon: +40 268 412 559

E-Mail: office@plastics-bavaria.ro

Route berechnen

Muntazah Complex (Exit - 25)

Jebel Ali Village - Dubai (VAE)

Telefon: +971 4 8845001

E-Mail: info@skz-me.com

Route berechnen

Ul. Kwiatkowskiego 5a

52-407 Breslau, Poland

Telefon: +48 71 35 84 000

E-Mail: dopak@dopak.pl

Route berechnen

SKZ – Testing GmbH

Friedrich-Bergius-Ring 22

97076 Würzburg

Tel. +49 931 4104-0