Find projects

Technology overview on polymer Additive Manufacturing

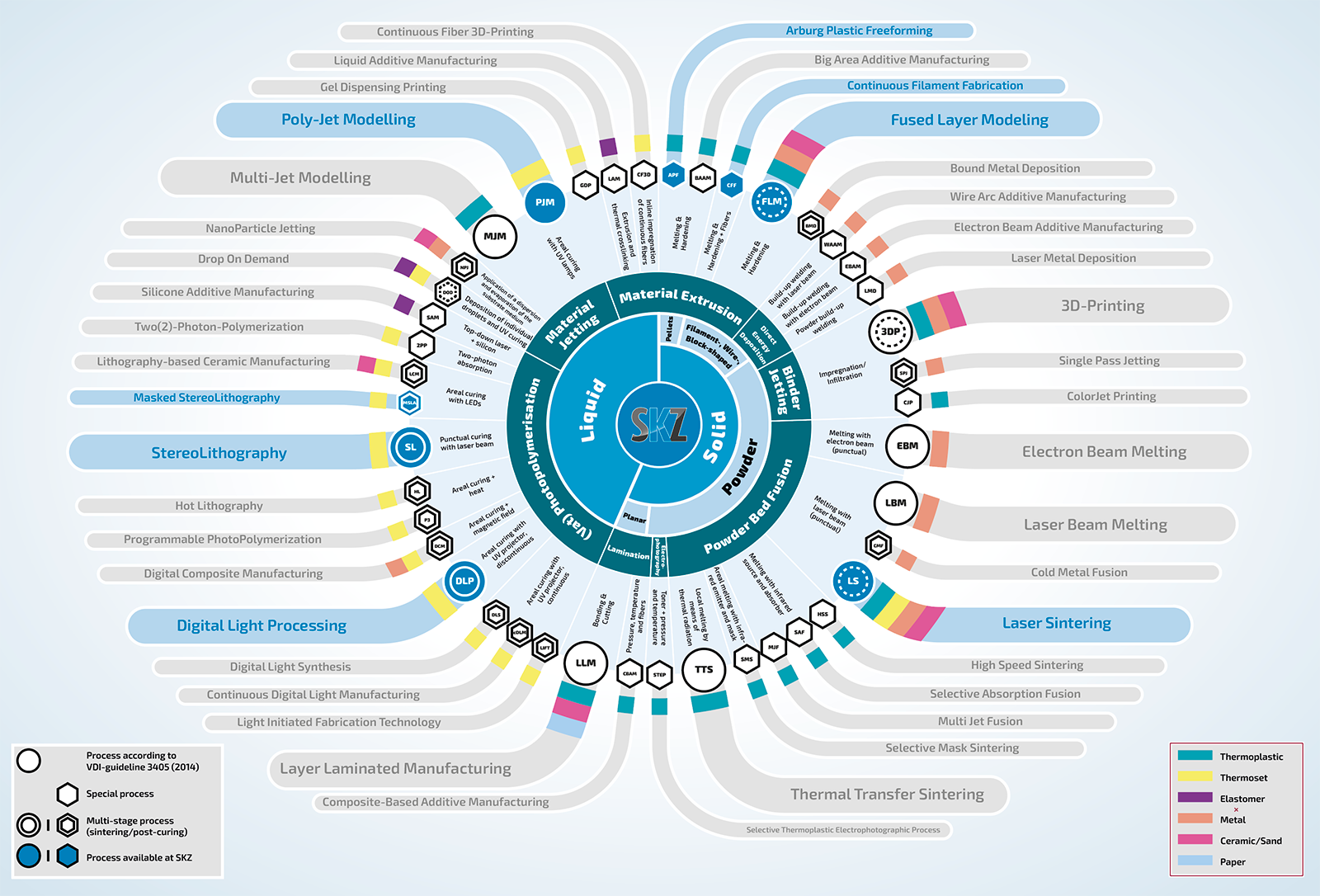

Take a look at the different additive manufacturing processes

Polymer Additive Manufacturing

The rapid development of 3D printing began in the early 1980s, driven by the need for fast and cheaper solutions to generate prototypes for mass production. Scientists from Japan, France and America had already been working on three-dimensional manufacturing technologies in the early 1980s.

Stereolithography is the forefather of additive manufacturing. The patent filed in 1986 by Charles "Chuck" Hull, who later founded the company 3D Systems, is considered the inventor of the process. In fact, a few years earlier, the Japanese Hideo Kodama was already experimenting with the curing of liquid resin using UV light. Three French researchers, Alain Le Mehaute, Olivier de Witte and Jean Claude André, were also working on the subject. While the Japanese lacked financial resources, the French did not pursue the invention any further because they did not see any marketing potential in it. Thus, to this day, Chuck Hull is considered the inventor of stereolithography.

The basic process of Fused Deposition Modeling (FDM) was developed and patented in the late 1980s by S. Scott Crump and his wife Lisa, both co-founders of Stratasys Ltd. Commercial application of the process, trademarked as Fused Deposition Modeling (FDM), followed in the 1990s. In 2005, Dr. Adrian Bowyer of the University of Bath in England initiated the RepRap project with the aim of developing a low-cost 3D printer including software as an open source project. In order not to come into conflict with Stratasys in terms of naming rights, the designation Fused Filament Fabrication (FFF) was simultaneously established as a freely usable name for the strand delivery process. Finally, the third and last abbreviation FLM (Fused Layer Modeling) goes back to the VDI (Association of German Engineers).

In addition to stereolithography and fused layer modeling, a large number of other processes still exist today. The number of these is also constantly increasing due to new developments. In addition to the large number of processes, there are now more and more materials that can be processed.

In our technology overview of additive manufacturing, we have grouped the technologies according to VDI guideline 3405. Processes that are difficult to classify here due to novel technology concepts are marked separately. In addition, the material categories that can be processed are also listed.

The additive manufacturing technologies available at SKZ are colored blue in the overview.

We are happy to support you with our know-how and provide the technologies for application-oriented research projects.

High resolution Polymer 3D Print Overview

We provide the technology overview in PDF format for free.

You are welcome to include the overview in your documents, stating the source.

Please send us an informal email if you are interested in the overview

of the technologies in 3D printing.

Request free 3D printing overview now

Need more information about additive manufacturing?

For further information or questions about additive manufacturing, processes

or construction for 3D printing, please contact us. We are happy to help.

Have a look on our research and training offerings at our competence center

for 3D printing processes (CAP).