SKZ invests in new plasma system for versatile surface modifications

The SKZ Plastics Center has expanded its equipment in the field of surface technology by purchasing a state-of-the-art plasma system - a Plasma Treatment Unit (PTU for short) - from Plasmatreat GmbH. Using atmospheric pressure plasma and a 6-axis robot, the system enables ultra-fine cleaning and activation of component surfaces made from a wide range of materials, including plastic, metal, glass and ceramics.

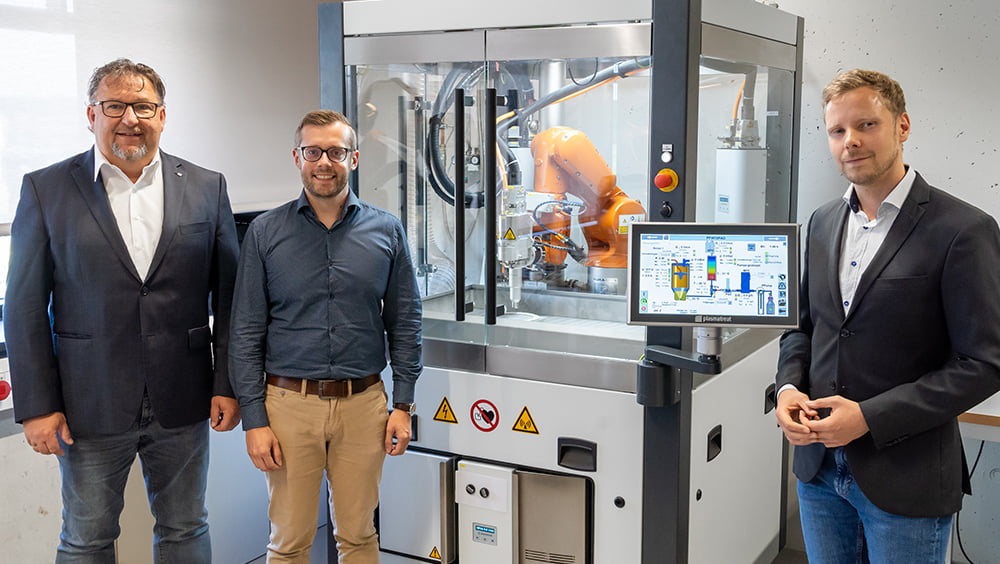

Joachim Schüßler (Plasmatreat GmbH), Michael Heilig and Christian Eck (both SKZ) at the commissioning of the plasma coating system (from left). (Photo: Luca Hoffmannbeck, SKZ)

The potential of plasma activation and coating for the plastics industry is to be further developed

Ultra-fine cleaning with atmospheric pressure plasma Openair plasma gently and reliably removes dust, release agents, additives, plasticizers and hydrocarbons from surfaces. The activation of surfaces through plasma treatment is used in particular for non-polar plastics and changes the surface properties from hydrophobic to hydrophilic. It supports the increase in surface energy through the introduction of hydroxyl groups and thus improves adhesion in subsequent processes such as bonding, printing, painting and sealing.

Functional layers in the nanometer range

"In addition to activating and cleaning surfaces, we can also use the system to apply functional layers in the nanometer range. In this application, a precursor is added to the plasma jet, which - depending on the composition - enables different functionalities on the surface. Examples of this include adhesion-promoting coatings for bonding or printing applications on plastic components and corrosion protection coatings on metallic components," explains Dr. Benjamin Baudrit, Deputy Managing Director of Education and Research at SKZ.

Treatment of free-form surfaces possible

The use of a 6-axis robot makes it possible to treat free-form surfaces and complex-shaped components. The plasma system opens up many degrees of freedom to further develop the potential of plasma activation and coating for the plastics industry. This applies in particular to the surface modification of components with fluctuating surface qualities, as is often the case with recycled components.

The facility is available to companies and partners of the SKZ for technology transfer as part of seminars, demonstrations and pilot applications.

More about the surface technology research area