From solid to melt: simulation of the melting process in a twin-screw extruder

The digital mapping and optimization of processes through numerical simulations is a key technology of Industry 4.0. However, such simulations reach their limits in plastics processing in particular, since the complex material behavior of plastics presents special challenges. The recently launched joint project between the Kunststoff-Zentrum SKZ (a plastics institute) and the Chair of Applied Mathematics and Numerics (LS3) at the Faculty of Mathematics at TU Dortmund is therefore focusing on the simulation of the melting of polymers in twin-screw extruders.

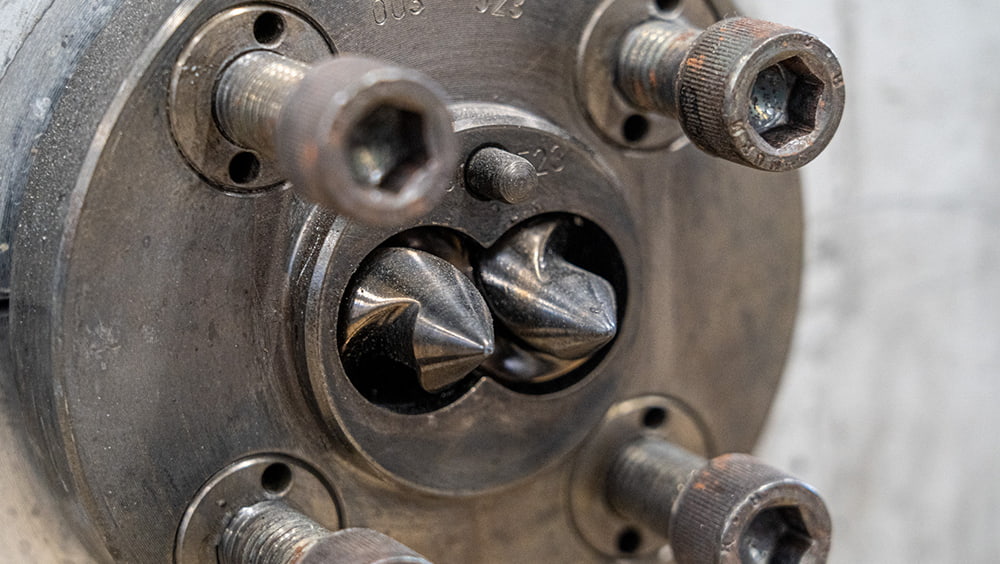

The twin-screw extruder is a widely used extruder type in plastics processing. However, it is not yet possible to simulate the melting behavior precisely. (Photo: Luca Hoffmannbeck, SKZ)

New research project “SimulAC” launched by SKZ and TU Dortmund

It is not yet possible to precisely simulate the melting of polymers in compounding extruders such as twin-screw extruders. This is slowing down the further development of these plants, which are indispensable for the production and recycling of plastics, and the processes based on them.

The aim of the newly launched project is therefore to develop a simulation that for the first time enables the numerical modeling of the melting process in a twin-screw extruder. The innovative solution combines approaches for the 3D simulation of melting from single-screw extruders, which are easier to model, with existing models for the processing of plastics in twin-screw extruders.

Melt fraction model plays a key role

The so-called melt fraction model, which describes the transition from solid to melt, plays a key role here. In order to implement this simulation method, the project will initially collect specific material data and define the necessary boundary conditions for the simulation. A test stand is being developed for validation purposes, which will enable experimental investigations. The comparison of simulation and experimental results finally serves to create a demonstrator simulation tool.

With the successful implementation, companies gain access to 3D simulations of the melting zone of a twin screw extruder. This opens up new possibilities for characterizing processes more precisely and optimizing industrial applications. Interested companies are welcome to contact SKZ or the LS3 at the TU Dortmund University.

The research project 01IF23298N is funded by the Federal Ministry for Economic Affairs and Climate Protection (BMKW) as part of the Industrial Collective Research (IGF).

More about compounding and extrusion at SKZ