Determining the degree of cure of applied adhesives non-destructively in the process

Non-destructive methods for testing adhesives that have already been applied are hardly established in the industrial environment, but have been increasingly researched in recent years. Dr. Giovanni Schober has now successfully completed his doctoral studies at Ilmenau Technical University on the use of air-coupled ultrasound technology in the curing of adhesives.

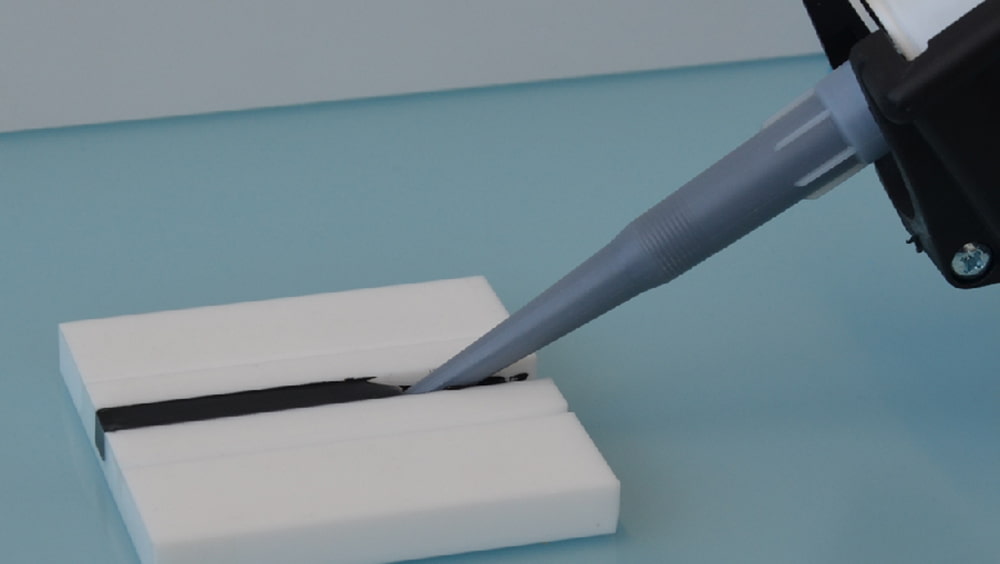

Application of a sealant into a joint (Photo: SKZ)

Dr. Giovanni Schober, head of the "Quality and Life Cycle" department at SKZ, successfully completes doctoral studies

Non-destructive testing makes it possible to characterize adhesives even when they are already between two substrates and thus no longer accessible from the outside. Here, the so-called air-coupled ultrasound technique in particular offers outstanding advantages. "Compared to the classic ultrasound technology familiar from doctors, systems of this kind can be used to record the curing of adhesives without contact and in real time. In this way, it is possible to reduce personnel and tool capacities depending on the real curing speed and thus independently of generally held manufacturer specifications. This saves money," explains Dr. Giovanni Schober, head of the "Quality and Life Cycle" department at the German Plastics Center SKZ, who has now successfully completed his doctoral studies on this topic at the Technical University of Ilmenau.

The new method offers unique possibilities to determine aggregate state changes in general, i.e. independent of the material system, possibly existing substrates and ambient conditions in real time. The fields of application extend far beyond the curing of adhesives and can be found, for example, in the melting and solidification of plastics of all kinds, the crosslinking of coatings and even the baking of foodstuffs. Interested companies are offered the opportunity to have the suitability of the new process for their own application tested at SKZ without incurring any costs.

Nowadays, adhesives are a central component in a wide variety of industrial segments and substitute or supplement conventionally applied joining methods such as welding and riveting. At the same time, numerous standardized test methods exist to characterize the curing of adhesives. However, these are limited to the examination of very small sample quantities in the laboratory on the basis of rheological and calorimetric methods, for example. The results obtained in this way cannot be directly transferred to the conditions in an industrial production environment due to unequal framework conditions.

Further information about research unit non-destructive testing