How computed tomography makes the inspection process more efficient

Computer tomography as a tool for non-destructive testing makes the testing process for plastics significantly more efficient. The SKZ Plastics Center offers numerous application possibilities here – from the analysis of fiber-filled and foamed plastic parts to the detection of internal defects, the recording and comparison of geometric features and density gradients, and coordinate metrology.

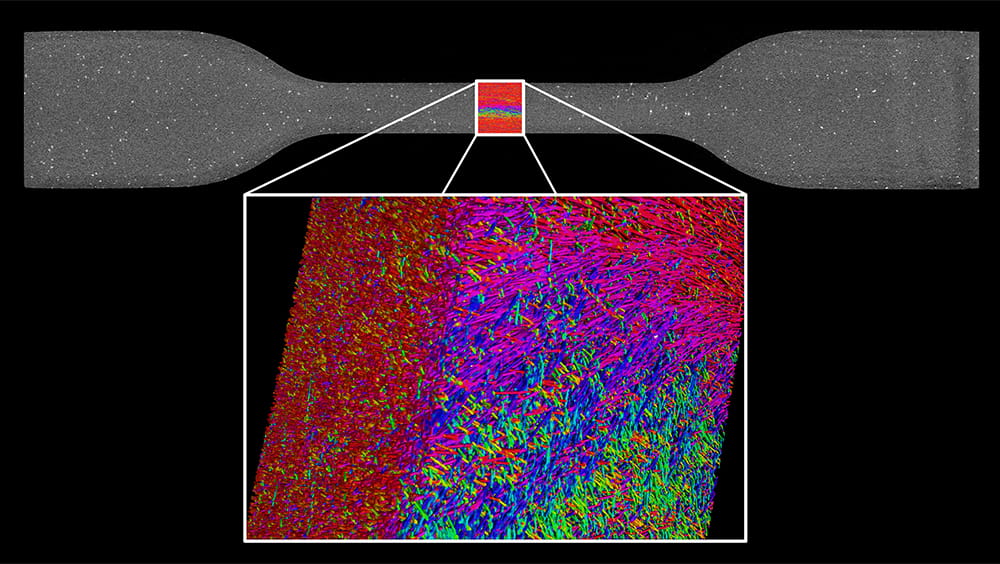

Computed tomography offers many possibilities, such as fiber analysis of a tensile rod. (Photo: Daniel Seewald, SKZ)

SKZ offers numerous application possibilities

One advantage of computed tomography for the non-destructive testing of plastics is the possibility of simultaneous high-resolution testing of several samples. This considerably speeds up the testing process, since, for example, several tensile bars can be scanned at the same time. In addition, the visualization of the smallest details, even on larger components, enables a non-destructive test, whereby the removal of sample sections is often no longer necessary. This not only saves time, but also maximizes efficiency in the testing process.

Resolution in the single-digit micrometer range possible

Thanks to the availability of different CT devices that work with high tube voltages, even larger plastic samples and various plastics, as well as thin metal layers, can be penetrated without difficulty. It is also possible to analyze samples in a resolution range down to the single-digit micrometer range. This means that even complex structures, such as the fiber structure of entire tensile bars, can be captured in just a single scan.

Contribution to product quality assurance

“With the knowledge gained from CT measurements as a tool for non-destructive testing, companies can make a decisive contribution to product quality assurance, optimize production processes and detect process errors more quickly,” says Daniel Seewald from the Non-destructive Testing Group at SKZ. ”We would like to invite companies to take advantage of the benefits of computed tomography at SKZ.”

More information about the SKZ research area of non-destructive testing