Cross-linking epoxy resin filaments for the FFF printer are intended to improve component properties

High-temperature thermoplastics often lead to problems such as warping, insufficient layer adhesion and distortion in the FFF printing process due to high process temperatures and strong temperature gradients. Latent reactive filaments based on epoxy resin are a promising alternative with comparable mechanical properties. These innovative materials enable processing at lower temperatures and crosslink during the printing process to form thermoset components. This allows the advantages of thermoplastic processing to be combined with the high performance of thermoset materials.

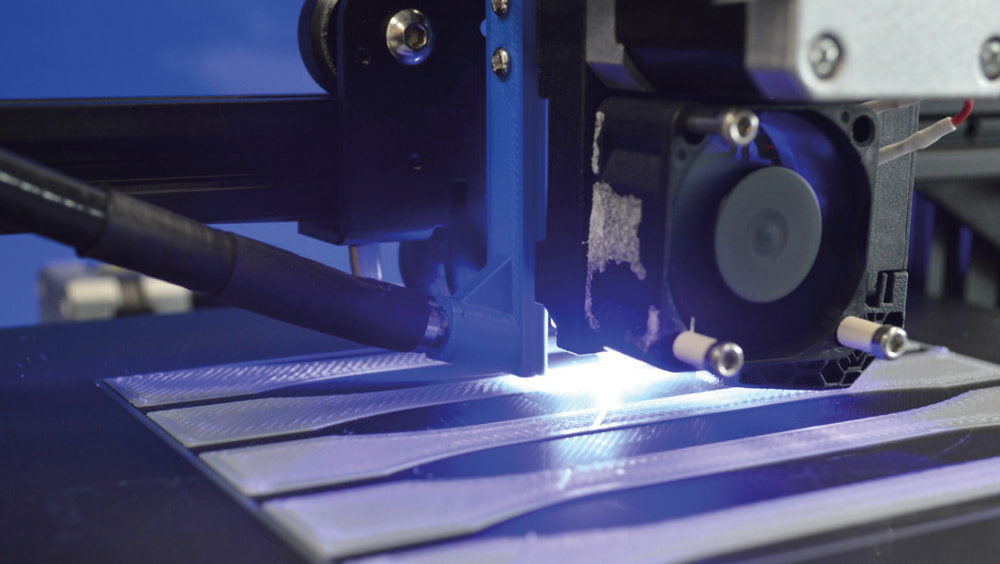

The filaments are processed in a conventional FFF printer and cross-linked with IR or UV radiation. (Source: Copyright @ Fraunhofer IFAM)

Challenges of conventional high-temperature FFF printing materials

The use of thermoplastic filament materials often leads to quality problems with printed components. This is particularly the case when parts are printed that have to withstand high temperatures during use. High-performance thermoplastics (e.g. PEI, PEEK or PPSU), which are manufactured at high process temperatures, are often used for this purpose. The direct consequences are strong temperature gradients between the printing nozzle and the component surface, high thermal stresses, insufficient layer adhesion, warping and dimensional deviations in the printed component due to shrinkage and warpage.

The new epoxy resin filaments offer an innovative solution here, in that shaping takes place at lower temperatures and cross-linking is only carried out afterwards.

SKZ and Fraunhofer IFAM cooperate in the "Reactive Printing" research project

Reactive epoxy resin filaments are currently being developed and investigated in the two-year IGF research project "Reactive Printing" (project number: 01IF23147N). The latently reactive epoxy resin filaments should be able to be cross-linked during the printing process and harden to form resistant duromers. To this end, the two research institutes, the SKZ Plastics Center in Würzburg and the Fraunhofer IFAM (Institute for Manufacturing Technology and Applied Materials Research) in Bremen, are pooling their expertise in the development and processing of the new filaments. The project is being supported by representatives from currently 25 companies.

Research objectives and advantages of the new filaments

The development of epoxy resin-based filaments is intended to solve the challenges of previous FFF printing materials. The most important advantages are

- Improved layer adhesion: reduced anisotropic material properties for more homogeneous components.

- Lower processing temperatures: No need for high performance thermoplastics.

- Access to thermoset fiber composite components in the FFF printing process.

- Hybrid components can be realized: Material-locking connections can be printed directly onto existing building structures made of different materials.

Solution

Initially, the resin formulation, accompanying material characterizations and the production of the filaments take place on a laboratory scale. An FFF printer will be set up for the tests, which will be used to characterize the printing properties and print test components. After the project, this will be available as a demonstrator. Upscaling is also planned by setting up a demonstrator system. In addition, numerical calculations on the melting and discharge behaviour of cross-linkable moulding compounds and the characterization of component properties will be carried out. At the end of the project, the process chain will be evaluated using practical components.

Company participation still possible

This project with the funding number 01IF23147N is being funded by the Federal Ministry for Economic Affairs and Climate Protection from 01.07.2024 to 30.06.2026 on the basis of a decision by the German Bundestag. Interested companies still have the opportunity to actively participate in the project committee.

Link to the project page