Find projects

Project: Customized joining for plastics and hybrid components with reactive multilayer systems (RMS)

Rapid developments have taken place in lightweight construction in recent years. This can be seen in the almost unlimited variety of materials and the increasingly complex joining technologies. In addition to lightweight metals and composite materials, the use of plastic components in particular offers great potential for saving weight and therefore CO2. It is not only necessary to join plastics of the same type with each other, but also with plastics of other types and with metals (hybrid construction). In addition to the requirement for high composite strength, there are often other requirements, e.g. with regard to ageing or mechanical resistance.

Conventional methods for joining lightweight components include bonding processes, mechanical fasteners or welding. Depending on the application, these joining processes have specific restrictions:

- Bonding processes are complex, require highly qualified personnel and introduce an additional component into the bond that is susceptible to ageing

- Mechanical fasteners such as screws or rivets lead to point stress increases in the bond compared to a flat load introduction

- Welding processes are particularly problematic when very pure connections are to be realized without weld expulsion or structural changes

The aim of this joint project, which we are carrying out together with the Fraunhofer IWS, is to use reactive multilayer systems (RMS) to overcome the limits of conventional joining technologies and to provide an alternative technology for customized joining in the plastics sector and in hybrid construction.

Duration: 12 month, planned start Q4/2022

Costs: approx. 10,000 € / company

Reactive multilayer systems

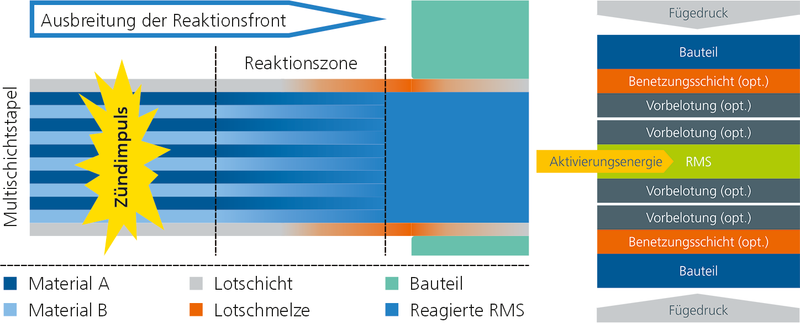

Reactive multilayer systems consist of at least two, sometimes three, chemical elements arranged alternately in thin layers. The total thickness of an RMS varies from a few micrometers to several tens of micrometers, whereby the individual layer thicknesses are in the range of a few nanometers. If an activation energy is introduced into this system, e.g. by an ignition pulse, a self-progressing, exothermic reaction occurs. The RMS reacts within fractions of a second and releases its binding enthalpy mainly in the form of heat and to a lesser extent as kinetic energy of the reaction products. The resulting heat can be used to join different materials, similar to soldering.

Image: RMS principle and joining process (Source: Fraunhofer IWS)

Content and goal

In this joint project, the RMS developed in previous projects are to be adapted and tailored specifically to your application. Various influencing factors will be investigated, such as the energy content of the RMS, the joining pressure or the geometry of the joining zone. Furthermore, the reactively joined plastic joints are to be analyzed with regard to the type and mechanism of joining, strength and long-term stability.

Your benefits

The targeted development of RMS joining technology provides users with a "modular system" with which, for example, dissimilar plastic joints can be produced according to the requirements of a specific product. SMEs in particular have the flexibility to use RMS joining in small and medium-sized series with different component sizes and geometric and functional requirements. In addition to these economic advantages for users, further opportunities for the successful use of the technology arise from the following aspects:

- Improvement of product properties by avoiding a high heat input into the environment of the joints

- Reduction of cycle times and production costs by reducing the effort involved in comparison with, for example, the preparation and curing of bonded joints

- Use of environmentally friendly technology due to low energy consumption and avoidance of substances that are hazardous to health or the environment

- Quick and easy automation of the joining technology in the process chain

- For SMEs that are already active in coating technology, the production and distribution of RMS as a film or by direct coating on one of the two joining partners could represent an attractive expansion of their existing product portfolio

Certain RMS, based on nickel and aluminum, can be purchased from the German company Innojoin GmbH and the American company Indium Corporation. In addition, these RMS and other RMS types can be purchased in small quantities from the Fraunhofer IWS.

Interested?!

If you would like to take part in this exciting research project, please send a short e-mail

Your request is non-binding. I will be happy to advise you personally on the planned process and further details. In enabler projects, you participate in a group of companies with a common goal for your specific business case. In the company of an expert, you can engage in an exchange and learn together how you can master specific challenges.

Did you know?!

You can claim research services for tax purposes under the Research Allowance Act! On the website of the Federal Ministry of Finance you can find out which legal framework conditions apply. We will be happy to advise you on further funding opportunities.

Please contact us if you have any questions.

We look forward to work with you on this topic and to take this alternative path in contract research.

Christian Eck

Joint project

in cooperation with