When plastics fatigue ...

If plastic components are subjected to cyclical loads, they fail at lower load levels than under a single load due to material fatigue. Experts at the SKZ Plastics Center are therefore working on ways to estimate this behavior more quickly and cost-effectively. In one research project, a physically based service life estimation was successfully implemented.

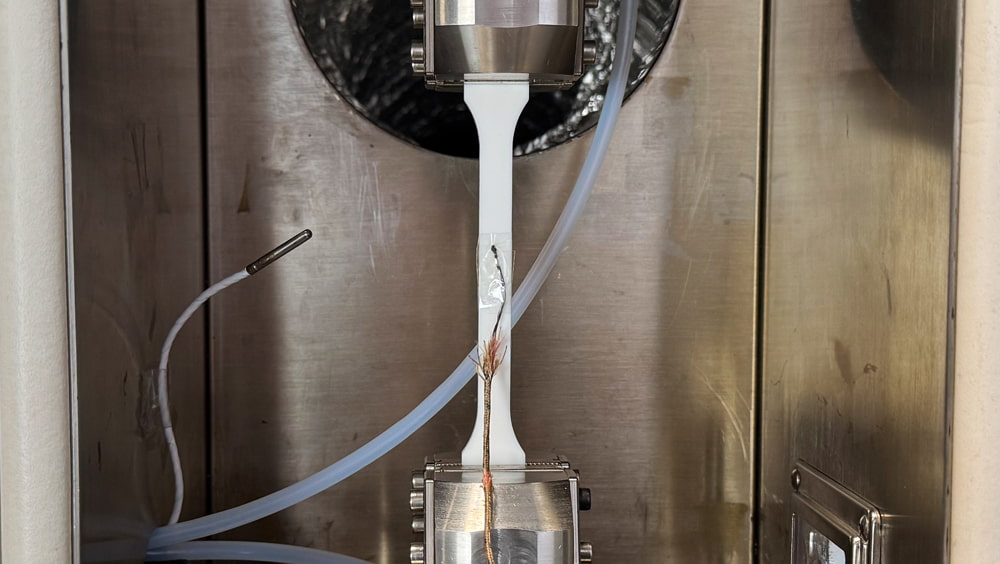

Tensile test specimen with thermocouple for measuring the surface temperature during the test on a vibration testing machine (Photo: Bertold Zugelder, SKZ)

Many plastic components are subject to cyclical loads during use.

Wöhler diagrams provide information about the service life. The information is given in the form of load cycles that can be endured until failure, depending on the external stress. Depending on the material behavior, a distinction can be made between short-term strength, fatigue strength and long-term strength. For component design, the fatigue strength range is often of particular interest, which for thermoplastics is generally in the range of 10,000 to 10,000,000 load cycles.

The time-consuming and cost-intensive experimental determination process is faced with ever shorter development times, increasing cost pressure and demands for resource efficiency. As part of a research project, researchers at the SKZ have therefore looked into the question of whether and how a physically based service life calculation can be implemented.

“By introducing a material-specific constant, we were able to develop the approach used in the metal sector for thermoplastics,” explains Britta Gerets, Senior Engineer at SKZ. Based on a force-controlled load increase test and two short force-controlled cyclic single-stage tests, a physically based calculation of the fatigue strength line (Wöhler line) is carried out. For this purpose, the measured variables strain amplitude, dissipated energy density and temperature change, which represent direct material responses to the stress variable, were used.

“Provided that the material-specific constant for the stress of interest is known, it was possible to demonstrate significant time and associated cost savings for estimating the fatigue strength range,” adds Dr. Ruben Schlutter, Group Manager Component Properties at SKZ.

More about the SKZ component properties research group