LSR using the 5-2-1 method

Five partners from the plastics industry have succeeded in producing two complex silicone molded parts in just one single tool. The tool - an example of successful cooperation in the plastics industry - is currently in use at the SKZ Plastics Center.

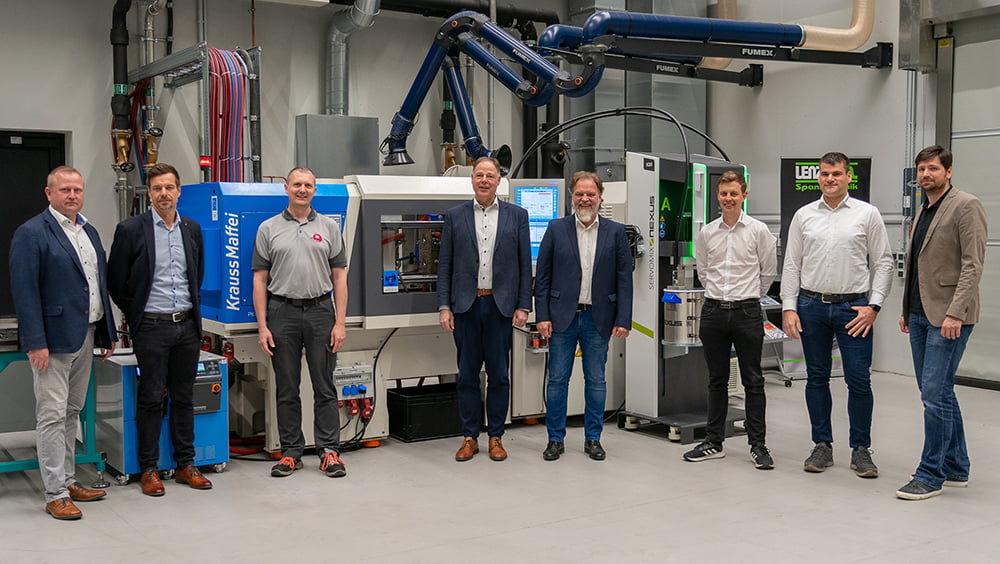

The project consortium in front of the LSR injection molding machine from KraussMaffei with the dosing system from NEXUS in the SKZ model factory. From left: Jürgen Ritter (Weschu), Sebastian König (Meusburger Georg GmbH & Co KG), Marcel Bestenlehrer (Bestenlehrer GmbH), Jörg Essinger & Torsten Schnell (GÜNTHER Heisskanaltechnik GmbH), Thomas Lender & Markus Scheuerlein (toolcraft AG) and Bernhard Hennrich (SKZ). (Photo: Luca Hoffmannbeck SKZ)

SKZ was able to produce two complex silicone molded parts in just one tool

Five partners from the world of plastics have embarked on an ambitious project: two molded parts made of liquid silicone (LSR), which could not have been more different in terms of their application and geometric dimensions, were to be produced in a single mold. On the one hand, a coffee lid with a shot weight of 28 g, a diameter of 100 mm and a maximum wall thickness of 7 mm was to be produced. On the other hand, a magnifying glass with a shot weight of only 6 g and a diameter of 35 mm with a lens with 6x magnification was on the agenda.

Solution approach: cold runner mold with valve gate

Supported by the expert advice of Dr. Ralf-Urs Giesen and his colleagues from the University of Kassel and thanks to the provision of system technology by KraussMaffei and NEXUS, SKZ and toolcraft AG have been able to press ahead with their developments over the past three years in the production cells set up on site. The significant differences in the shot weight of the two articles quickly led to a solution approach with a cold runner mold with valve gate.

“Precise and stepless adjustment of the needles”

Innovation partner GÜNTHER Heisskanaltechnik GmbH provided its valve gate nozzle with electric linear actuator for this purpose and, due to the space available on the machine's clamping unit, supplemented it with drives offset by 90 degrees. “It quickly became clear to us that this project was a unique and good opportunity to test our cold runner system in practice,” says Torsten Schnell, Head of Research and Development at GÜNTHER Heisskanaltechnik GmbH. “The electric linear actuators allow precise and infinitely variable adjustment of the needles for optimum filling of different component sizes in one mold,” adds Jörg Essinger, Head of Application Technology.

Stable growth in the silicone market

Meusburger Georg GmbH & Co KG contributed to the consortium with its expertise in selecting the right material for the tool steels used. “The silicone market is a stable and growing market. For us at Meusburger it was important to expand our expertise here even more in order to be able to advise customers in the best possible way,” emphasizes Sebastian König, Regional Sales Manager at Meusburger. For the planned injection mold, corrosion-resistant steels were proposed and ultimately used for the basic structure and the mold inserts.

Polishing demanding cavities

Bestenlehrer GmbH, a tool and mold making company, is a recognized expert in the field of polishing complex cavities. The second-generation family business specializes in the distortion-free and contour-accurate polishing of injection moulding, die casting and forming tools. “Long-standing and highly qualified specialists as well as modern workplaces must be our claim when it comes to the individual requirements of our customers,” explains Marcel Bestenlehrer, Managing Director of Bestenlehrer GmbH.

Recognizing trends at an early stage

“Only through close cooperation like this is it possible to expand the company's own portfolio and build up the necessary network alongside day-to-day business. The SKZ provides us with a wide range of opportunities to exchange ideas with other industry representatives,” adds Markus Scheuerlein, Project Manager Mold Making at toolcraft AG. “The contacts we make at the specialist conferences allow us to identify trends at an early stage and drive innovation forward,” he continues. The expertise built up over decades in the field of mold making for highly demanding precision small parts is the solid starting point for toolcraft to manufacture the silicone mold within the project. In addition to the ongoing “SiliTemp” research project with the SKZ, toolcraft is now also developing and building the first silicone tools for industry.

Possible PFAS ban likely to drive sales of LRS

“The nice thing about the plastics industry and my job is that after 16 years of professional experience, you can still get to know new materials or classes of materials that are fascinating,” explains Bernhard Hennrich, Group Manager Injection Molding Research at SKZ. “Especially when you are entering new subject areas, competent, reliable and cooperative companions are worth their weight in gold. You also need a good dose of pragmatism, which is present in all project partners at all times,” continues Hennrich. The SKZ supported the component design with rheological simulations of the filling behavior and degree of cross-linking. Growth rates in the silicone market have been in the double-digit range for several years despite the weakening economic situation. The impending PFAS ban will certainly continue to drive LSR sales in the coming months - as the inquiries from the industry already confirm.

Tool can be viewed at the SKZ during the network week

The jointly developed tool will be available to the SKZ for research and education in the future. The SKZ would like to thank all partners involved and those who have worked in the background. Interested parties are cordially invited to experience the tool live in action at the SKZ Network and Technology Day on June 26 and 27 in Würzburg in the model factory at the SKZ.

More information on injection molding research at the SKZ

More information about the SKZ training program